Description

Cascade PMV200 Vacuum Probe System for Advanced Wafer Testing

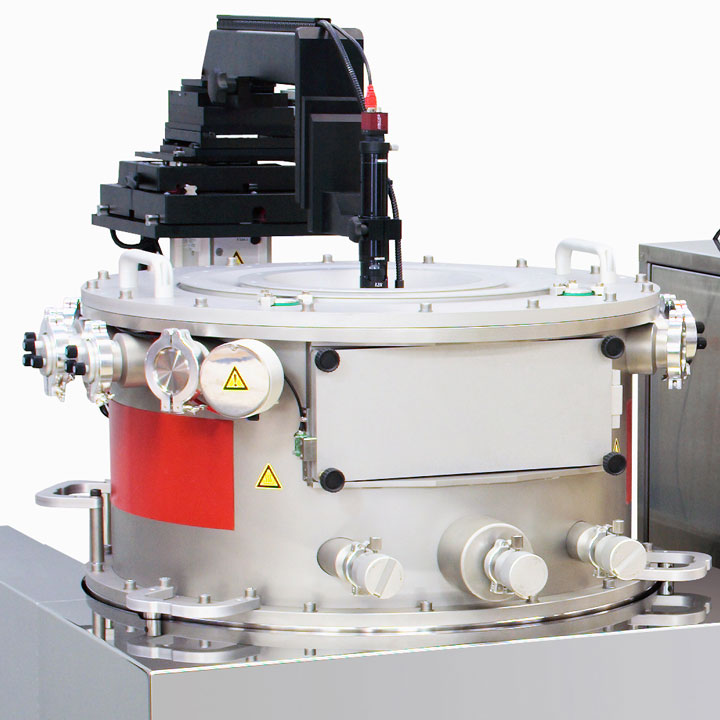

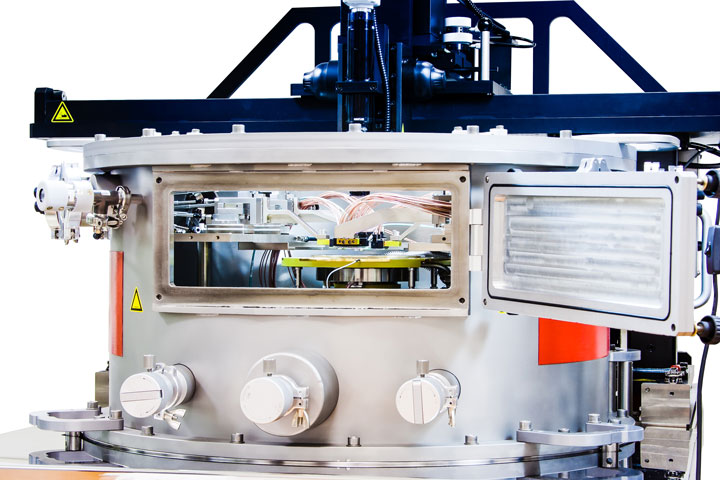

The Cascade PMV200 200 mm Manual Vacuum Probe System is a high-performance probe station designed for advanced manual wafer probing in a high-vacuum environment down to < 1×10⁻⁴ mbar. Engineered for precision and versatility, the PMV200 offers exceptional measurement stability, making it the perfect solution for both educational research laboratories and industrial testing facilities.

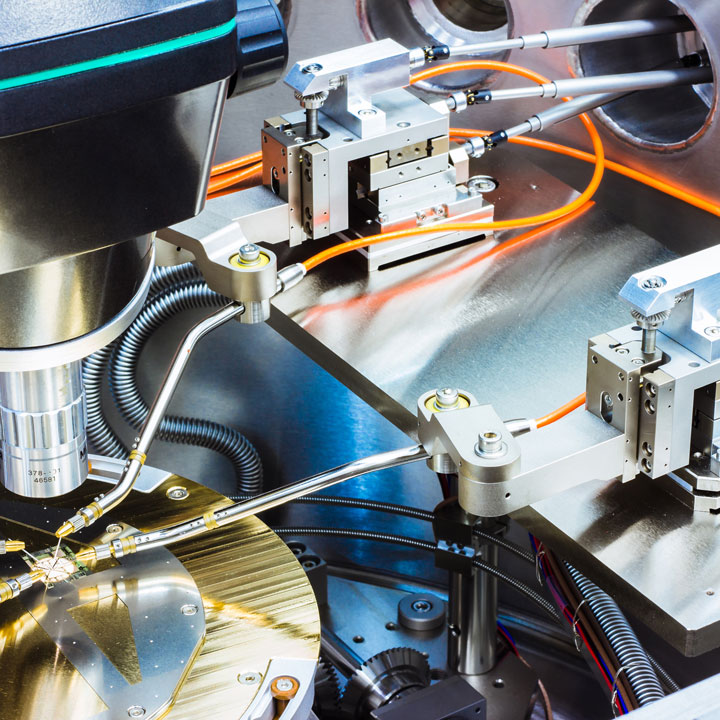

This system accommodates wafers and substrates up to 200 mm or individual dies, providing flexibility for a wide range of testing needs. Equipped with up to eight positioners and compatible with probe cards, the PMV200 supports an extensive portfolio of measurement applications, including DC, C-V, RF, MEMS, and optoelectronic analysis. For specialized testing, users can enhance functionality with optional accessories such as black bodies and optical motion analysis tools.

One of the standout features of the PMV200 is its thermal chuck option, offering temperature control between -60°C and 300°C, ensuring reliable performance in temperature-sensitive experiments. The system is also upgradeable to support 300 mm wafers, making it a future-proof investment.

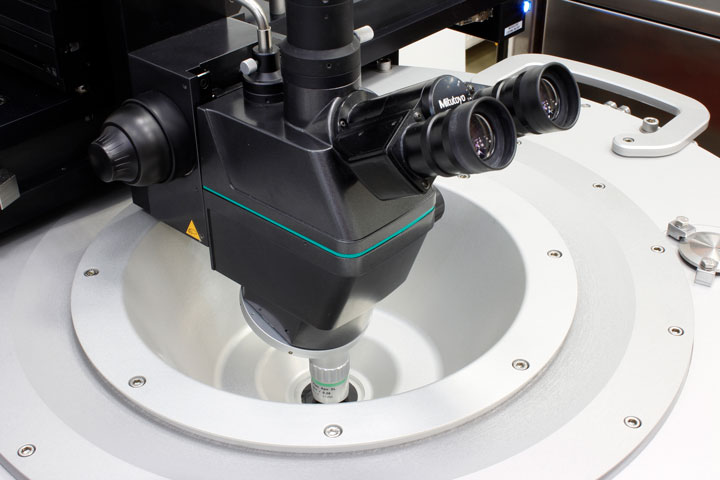

Stability and accuracy are at the core of the PMV200’s design. With short, stable probe arms and probe positioners located inside the vacuum chamber, users benefit from excellent measurement repeatability and superior vibration attenuation. An optional microscope bridge enhances imaging stability, critical for demanding MEMS analysis.

Ease of use is built into every aspect of the PMV200. Its ergonomic design includes manual drives for intuitive operation and front-loading capability, allowing quick and effortless device-under-test (DUT) changes. Combined with software-controlled chuck movement, the system enables fast step-and-repeat testing across entire wafers, maximizing throughput and efficiency.

Whether for precision MEMS analysis, optoelectronic device testing, or advanced wafer measurements, the Cascade PMV200 Manual Vacuum Probe System delivers the accuracy, flexibility, and throughput required by today’s researchers and engineers.

Technical Specifications

| Feature | Specification |

| Wafer Size | Up to 200 mm (optional upgrade to 300 mm) |

| Substrate Support | Wafers and single dies |

| Positioners | Up to 8, with probe card compatibility |

| Vacuum Level | < 1×10⁻⁴ mbar |

| Temperature Control | Optional thermal chuck, -60°C to +300°C |

| Accessories | Black bodies, optical motion analysis tools |

| Stability | Built-in vibration isolation, short stable probe arms |

| Microscope Options | Optional bridge for stable imaging |

| Operation | Manual drives, ergonomic design, front loading |

| Throughput | Software-controlled chuck, fast step-and-repeat |

| Applications | DC, C-V, RF, MEMS, optoelectronic testing |

Click here to learn more about similar products from FormFactor Beaverton Inc.