Description

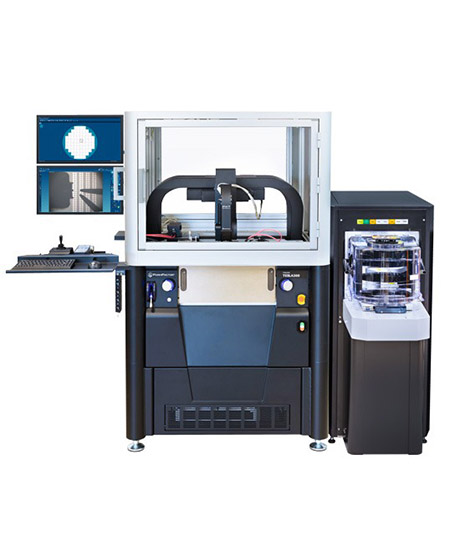

Cascade TESLA300 Power Device Probe System

The Cascade TESLA300 is an advanced 300 mm semi- and fully-automated power semiconductor probe system designed for high-voltage and high-current device characterization. Engineered for both engineering labs and production environments, it delivers precision, safety, and flexibility for next-generation power devices.

The TESLA300 enables on-wafer testing up to 10,000 V DC and 600 A, making it ideal for evaluating high-power components in electric vehicles, renewable energy, and industrial electronics. Its AttoGuard™ and FemtoGuard™ thermal chuck technologies provide a fully shielded, low-leakage test environment, ensuring unmatched accuracy for Rds(on), UIS, and high-temperature measurements. The MicroVac™ chuck supports thin wafer handling with minimal resistance and maximum dissipation, reducing breakage and boosting measurement reliability.

Operator safety is central to TESLA300’s design. With TÜV-certified interlocks, a full enclosure, and ergonomic roll-out chuck access, users can safely conduct high-power tests. The TopHat thermal system enables stable measurements across -60°C to +300°C, ensuring repeatability under real-world conditions.

The Material Handling Unit (MHU301) further enhances throughput with automated wafer loading, barcode recognition, and FOUP/FOSB support. For seamless integration, TESLA300 connects effortlessly with Keysight and Keithley analyzers, while the Velox software suite simplifies operation with intuitive alignment tools, automated test workflows, and touchscreen access through Velox Dash™.

Remote operation capabilities allow engineers to place probes, manage wafer maps, and run test programs securely from anywhere, ensuring productivity without compromising safety. Proven technologies, field-upgradeable options, and customizable setups make TESLA300 a long-term investment that adapts to evolving test requirements.

From precise Rds(on) analysis to high-volume wafer probing, the Cascade TESLA300 sets the standard for reliable, efficient, and autonomous power device testing.

Technical Highlights of Cascade TESLA300

| Feature | Specification / Capability |

| Wafer Size | 200 mm and 300 mm |

| Voltage / Current Range | Up to 10,000 V DC / 600 A |

| Chuck Technologies | AttoGuard™, FemtoGuard™, MicroVac™ |

| Thermal Range | -60°C to +300°C with TopHat |

| Safety Certification | TÜV-certified interlock and enclosure |

| Wafer Handling | Roll-out chuck, MHU301 with FOUP/FOSB, barcode recognition |

| Automation | Velox and VeloxPro with SEMI E95 compliance |

| Remote Operation | Full probe control, wafer mapping, and live monitoring |

| Auxiliary Chucks | High-voltage 10 kV mounts for cleaning and substrate tests |

| Supported Probes | High-voltage and high-current probes up to 600 A / 10 kV |

Click here to learn more about similar products from FormFactor Beaverton Inc.