3-Phase 4-Wire Power Quality Analyzer Compliant to IEC61000-4-30 Class S Standards and On-screen Guide to Deliver Easy Setup and Testing

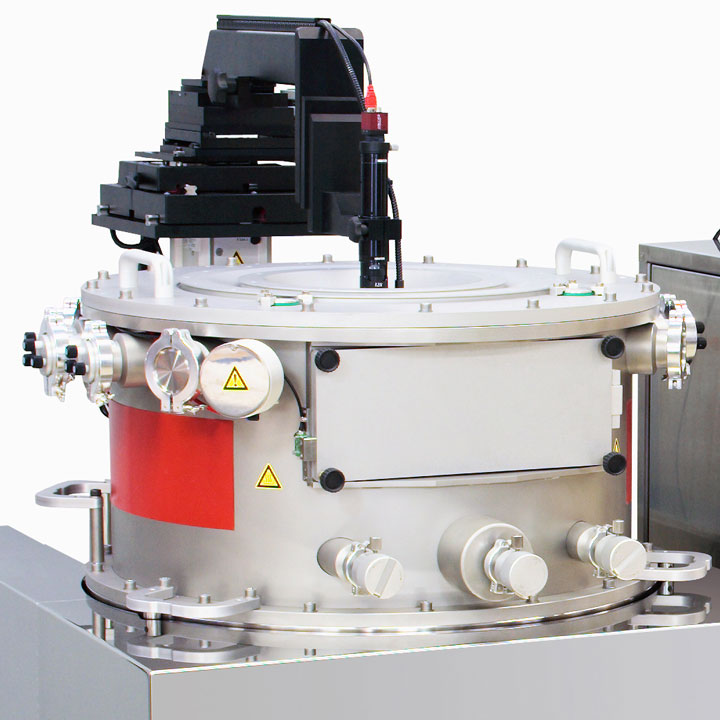

FormFactor Cascade PAP200 200 mm semi-automated vacuum and pressure probe system

- Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Optional thermal chuck (-60°C to 300°C) and pressure regulation

- Stability

- Probe positioners placed inside vacuum chamber

- Short and stable probe arms

- Solid station frame with built-in vibration-isolation

- Optional microscope bridge

- Precise probe positioning

- Ease of Use

- Joystick controller

- Manual probe positioners with rotary feed-throughs

- Front loading capability through load door

- High measurement throughput

- Software control of chuck for fast step-and-repeat testing of the entire wafer

- Fast step-and-repeat testing of the whole wafer

Introducing the FormFactor Cascade PAP200 200 mm semi-automated vacuum and pressure probe system

Cascade PAP200LP from FormFactor probe system from FormFactor is the ideal probing solution for testing MEMS pressure sensors with high accuracy at above/below atmospheric air pressure. The entire 200 mm prober is integrated into a pressure chamber rated from 500 mbar to 1200 mbar absolute.

To meet the production test requirements, the PAP200LP is equipped with a highspeed 200 mm chuck stage, designed for use with standard 4.5” probe cards. The modular design of the PAP200LP enables a wide range of measurements, including I-V for piezo-resistive and C-V for capacitive pressure sensors.

The PAP200LP is equipped with a stable vibration isolating frame. The pressure chamber with topside viewport and an optical window made of quartz glass contains flanges for vacuum-tight electrical feedthroughs. The pressure control system consists of a powerful diaphragm vacuum pump, a remote controlled proportional valve for air dosage and a high-precision pressure sensor to monitor the environmental conditions.

All main functions, i.e. stage movement and pressure control, can be controlled by software. The large front door allows quick and ergonomic loading and unloading of the wafer, as well as easy probe card exchange. A swivel mechanism, which is part of the microscope station, allows convenient access to the topside lid.

The PAP200LP can be customized with a variety of instrumentation, such as video microscopes, laser cutters and Polytec’s optical motion analysis tools. Specially designed thermal chucks, with electrical and coolant bulk feed throughs, are available for the use under vacuum conditions. The PAP200LP supports a wide temperature range from -60°C to 200°C , and a dew point

sensor ensures condensation-free probing.

Key Features

Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Optional thermal chuck (-60°C to 300°C) and pressure regulation

- Accessories available, such as black bodies and optical motion analysis tools

- Optional upgrade for 300 mm wafer

- Designed for industrial environments

- Covers wide range of measurements (I-V, C-V, RF, MEMS, OPTO)

- Ideal for small structures

Stability

- Probe positioners placed inside vacuum chamber

- Short and stable probe arms

- Solid station frame with built-in vibration-isolation

- Optional microscope bridge

- Precise probe positioning

- Excellent measurement accuracy and repeatability

- Superior vibration attenuation

- Stable image quality for demanding MEMS analysis

Ease of use

- Joystick controller

- Manual probe positioners with rotary feed-throughs

- Front loading capability through load door

- Comfortable and easy operation

- Quick and ergonomic change of DUT

High measurement throughput

- Software control of chuck for fast step-and-repeat testing of the entire wafer

- Fast step-and-repeat testing of the whole wafer

Velox Probe Station Control Software

- User-centered design minimizes training costs and enhances efficiency

- Comprehensive alignment functions – from simple wafer alignment and mapping to automated alignment and test of multiple singulated chips, like IR – Focal Plane Arrays

- Simplified operation for inexperienced users: Reduced training costs with Workflow Guide and condensed graphical user interface

- VeloxPro option: SEMI E95-compliant test executive software that enables simplified and safe automation of the entire wafer test cycle

Key Benefits

| High throughput | • Patented wafer-exchange mechanism for quick loading / unloading • High-speed stage with up to five dies/s without compromising accuracy |

| Ease of use | • Large front door for easy probe card exchange • All main functions controlled by software |

| Flexibility | • Several flanges for flexible configuration • Electronics rack providing space for test instruments |

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

| Chuck Stage | |

| Travel | 205 mm x 205 mm |

| Resolution | 1.0 µm |

| Repeatability | ± 2.0 µm |

| Accuracy | ± 5.0 µm |

| Z Movement | DC servo with linear encoder feedback |

| Travel | 15 mm |

| Resolution | 0.25 µm |

| Repeatability | ± 1.0 µm |

| Theta Movement | DC servo with linear encoder feedback |

| Travel | ± 6.0º |

| Resolution | 0.0001º |

| Pressure Supply System | |

| Range | 500 to 1200 mbar absolute (other on request) |

| Accuracy | ± 0.05 % of full range (± 0.025 on request) |

| Electrical Data | |

| System power (internal) | System power (internal) |

| Utilities Required | |

| Compressed air input | 0.5 MPa to 0.6 MPa or 5 bar to 6 bar; hose of 8 mm outer diameter |

| N2 input | Class 4.6 or better; 4 bar; 8 mm outer diameter tube |

| Exhaust | 50 mm hose |

| Microscope | |

| Type | Fits to video and stereo microscopes |

| Probe Platen | |

| Type | 4.5” probe card adapter |

| Chucks | |

| Standard | 150 mm or 200 mm; stainless steel |

| Thermal | 200 mm; -60°C to 200°C |

Data, design and specification depend on individual process conditions and can vary according to equipment configurations. Not all specifications may be valid simultaneously.

Datasheet