Description

The Hioki BT6065 and BT6075 Precision Battery Testers are advanced instruments designed to meet the growing demands of electric vehicle (EV) battery testing. These testers deliver exceptionally accurate OCV (open-circuit voltage) and AC-IR (alternating current internal resistance) measurements, enabling manufacturers and researchers to perform precise cell grading and screening for high-capacity, low-resistance battery cells.

Precision and Speed for Reliable Testing

With industry-leading accuracy, the BT6065 offers 6½-digit resolution (10 µV, 0.01 µΩ), while the BT6075 pushes performance further with 7½-digit resolution (1 µV, 0.01 µΩ). This high resolution ensures stable measurements even on low-resistance EV cells, providing the reproducibility necessary for efficient production testing. A fast response time (as low as 8 ms) shortens overall testing cycles, boosting throughput.

Interference-Free Parallel Operation

Unique to Hioki, the MIR (Mutual Interference Reduction) mode allows two testers to operate in close proximity without signal distortion. This makes parallel high-speed testing practical and reliable, reducing the need for costly synchronization accessories.

Advanced Compensation and Monitoring

The BT6065 and BT6075 integrate referential adjustment for up to 528 channels, compensating for eddy currents that often distort multi-battery tray measurements. The built-in route resistance monitor detects probe wear or wiring degradation, predicting maintenance needs before errors occur. This ensures continuous uptime and lowers operating costs.

Seamless System Integration

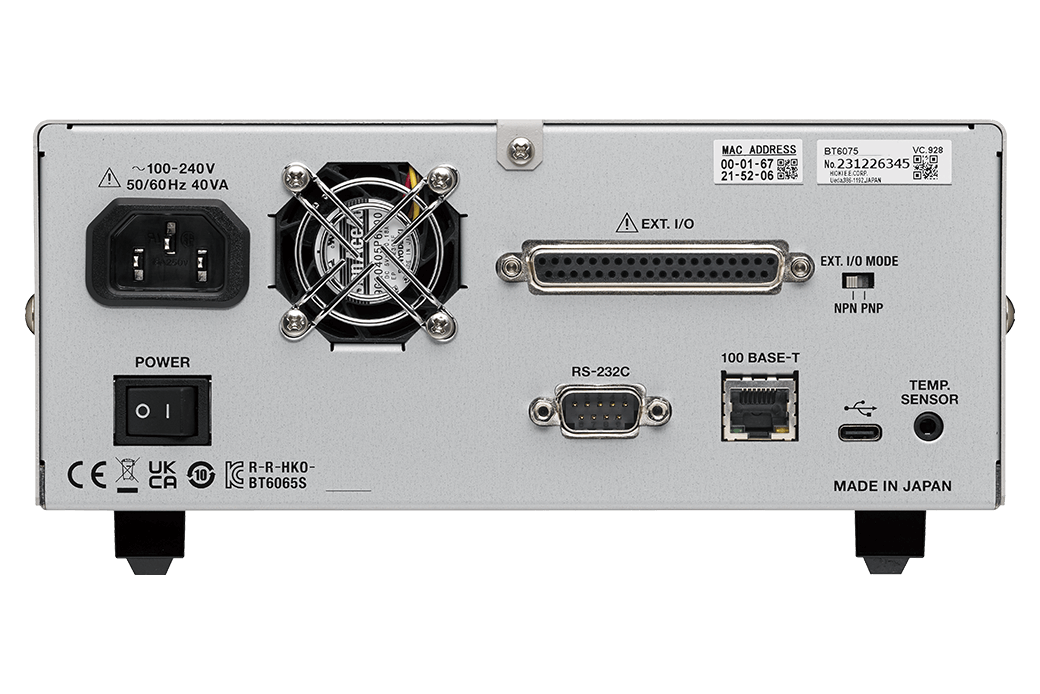

Both models are compatible with BT3562A HiTester commands, allowing easy upgrades without rewriting communication protocols. A wide range of interfaces (LAN, USB, RS-232C, EXT I/O) supports smooth integration into automated testing systems.

Built for durability, precision, and efficiency, the Hioki BT6065 and BT6075 are ideal for EV manufacturers, battery research facilities, and high-volume production lines seeking long-term stable performance in demanding environments.

Technical Highlights – Hioki BT6065 & BT6075

| Specification | BT6065 | BT6075 |

| Measurement Function | OCV and AC-IR testing | OCV and AC-IR testing |

| Resolution (DCV) | 10 µV (6½ digits) | 1 µV (7½ digits) |

| Resolution (AC-IR) | 0.01 µΩ | 0.01 µΩ |

| Voltage Range | Up to 120 V | Up to 120 V |

| Resistance Range | 3 mΩ – 30 Ω | 3 mΩ – 30 Ω |

| Accuracy | ±0.08% rdg. ±0.08 µΩ (300 mA current) | ±0.08% rdg. ±0.08 µΩ (300 mA current) |

| Parallel Testing Mode | MIR (Mutual Interference Reduction) | MIR (Mutual Interference Reduction) |

| Referential Adjustment | Up to 528 channels | Up to 528 channels |

| Interfaces | LAN, USB, RS-232C, EXT I/O | LAN, USB, RS-232C, EXT I/O |

| Applications | Cell screening, formation, aging | BOL/EOL testing, advanced grading |

Click here to learn more about similar products from HIOKI E E CORPORATION.

Hioki POWER METER PW3337

Hioki POWER METER PW3337