Description

Cascade TESLA200 automated wafer power device characterization

`

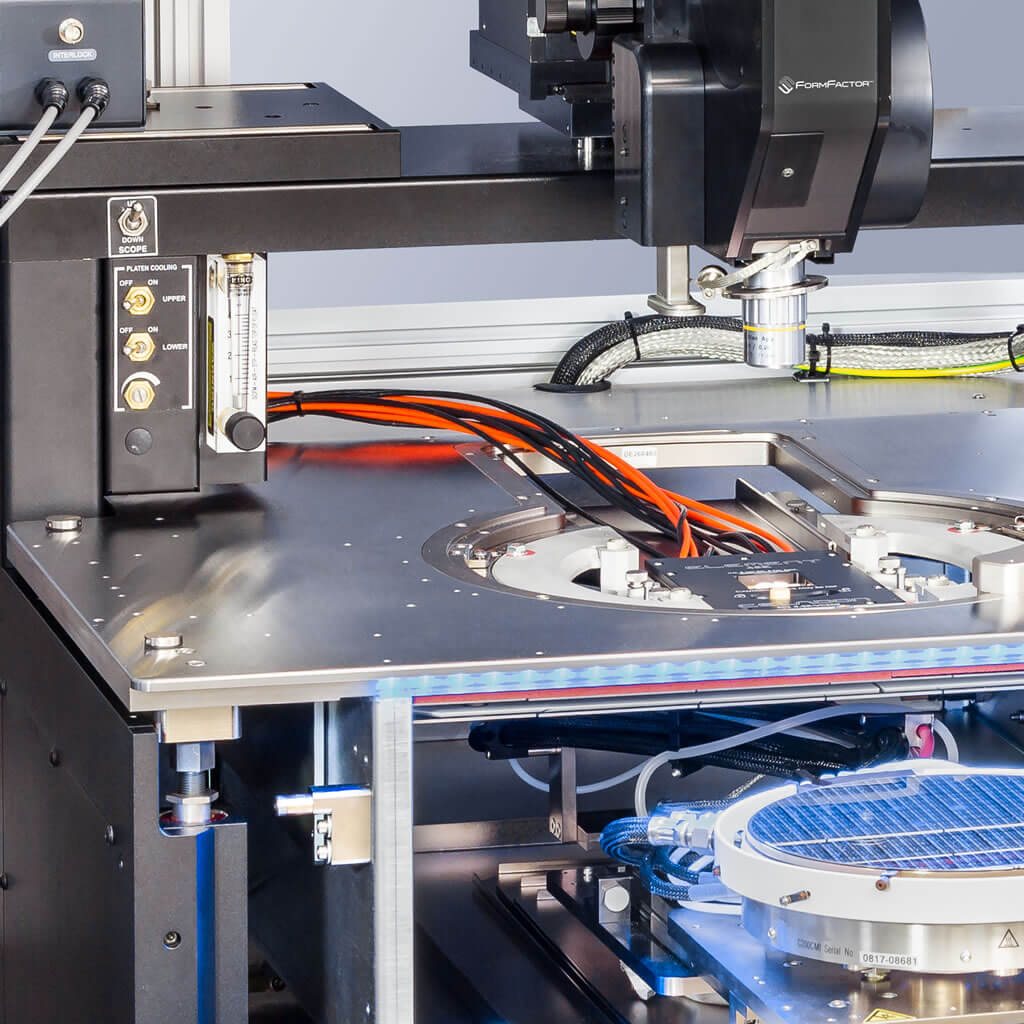

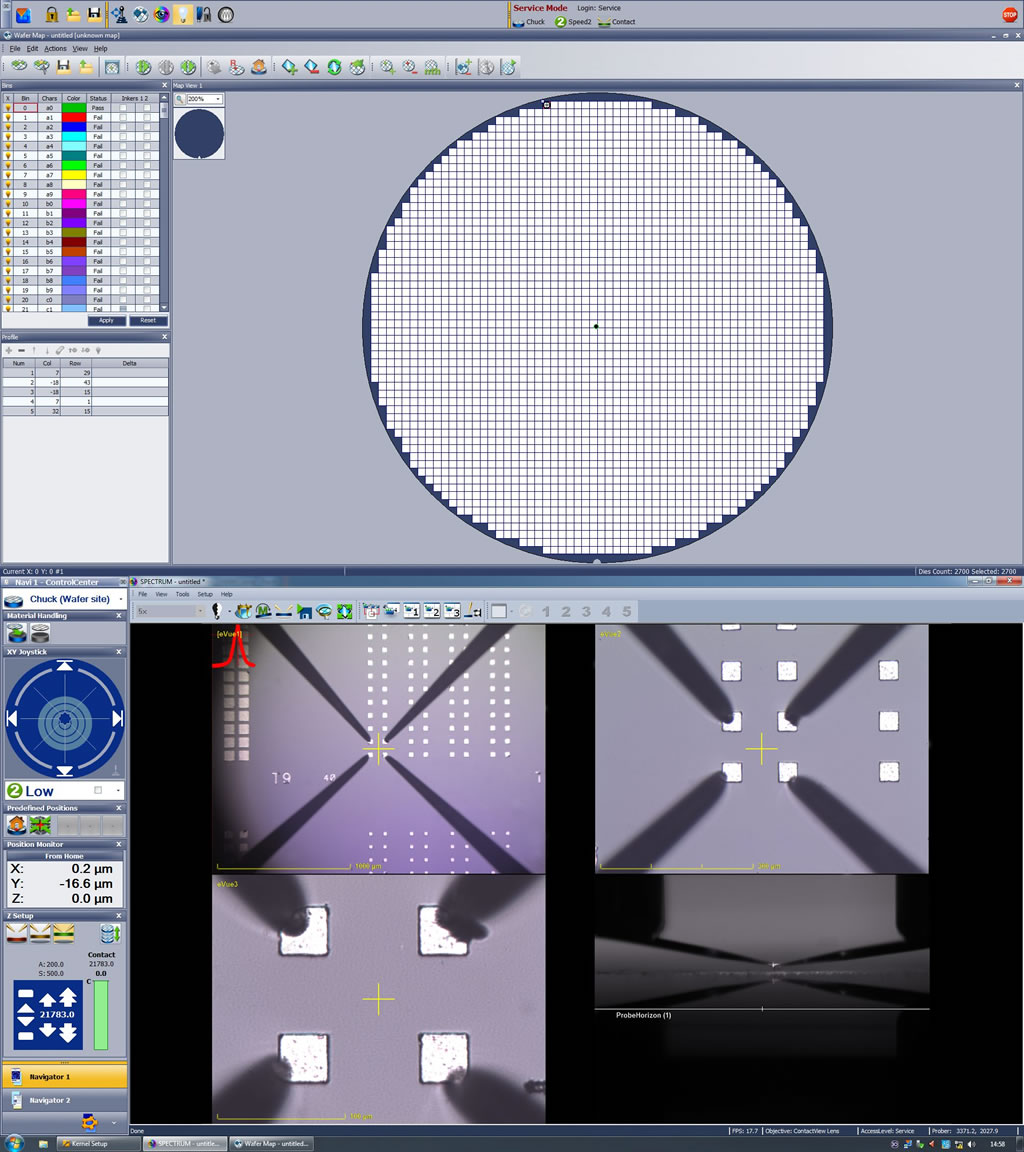

TESLA200 Overview

Designed specifically for IGBT/power MOSFET (GaN, SiC, Si) device measurements at the wafer level, the new TESLA200 on-wafer power semiconductor probing system is engineered to provide accurate data up to 3, kV (triaxial) / 10 kV (coaxial) and 200 A (standard) / 600 A (high current). With next generation test capabilities, anti-arcing solutions, wafer automation, and support for both engineering probes and production probe cards, the TESLA200 now enables complete thermal testing (-55°C to 300 °C) with fully-automatic thinned/warped/TAIKO wafer loading. One system covers all on-wafer high power test needs, from R&D to niche production.

Applications: High Power

TESLA200 Key Features

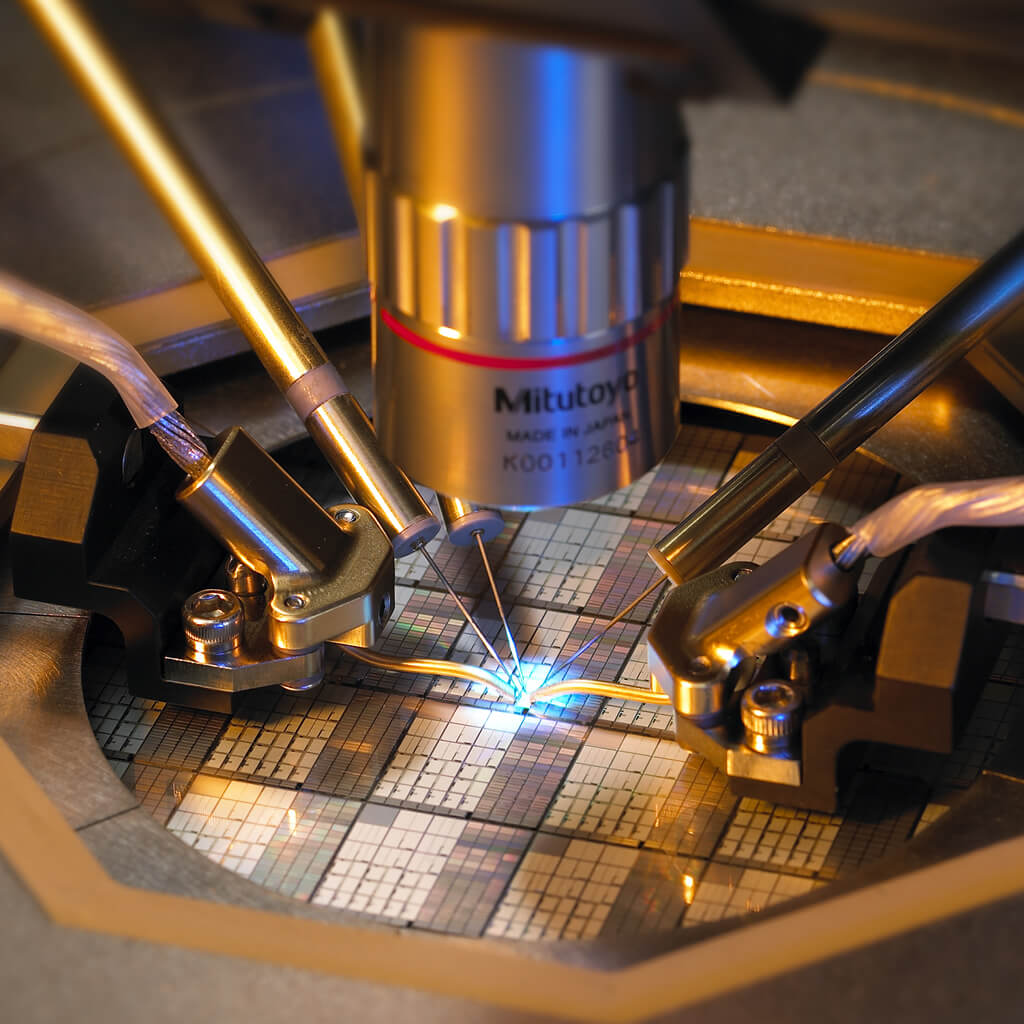

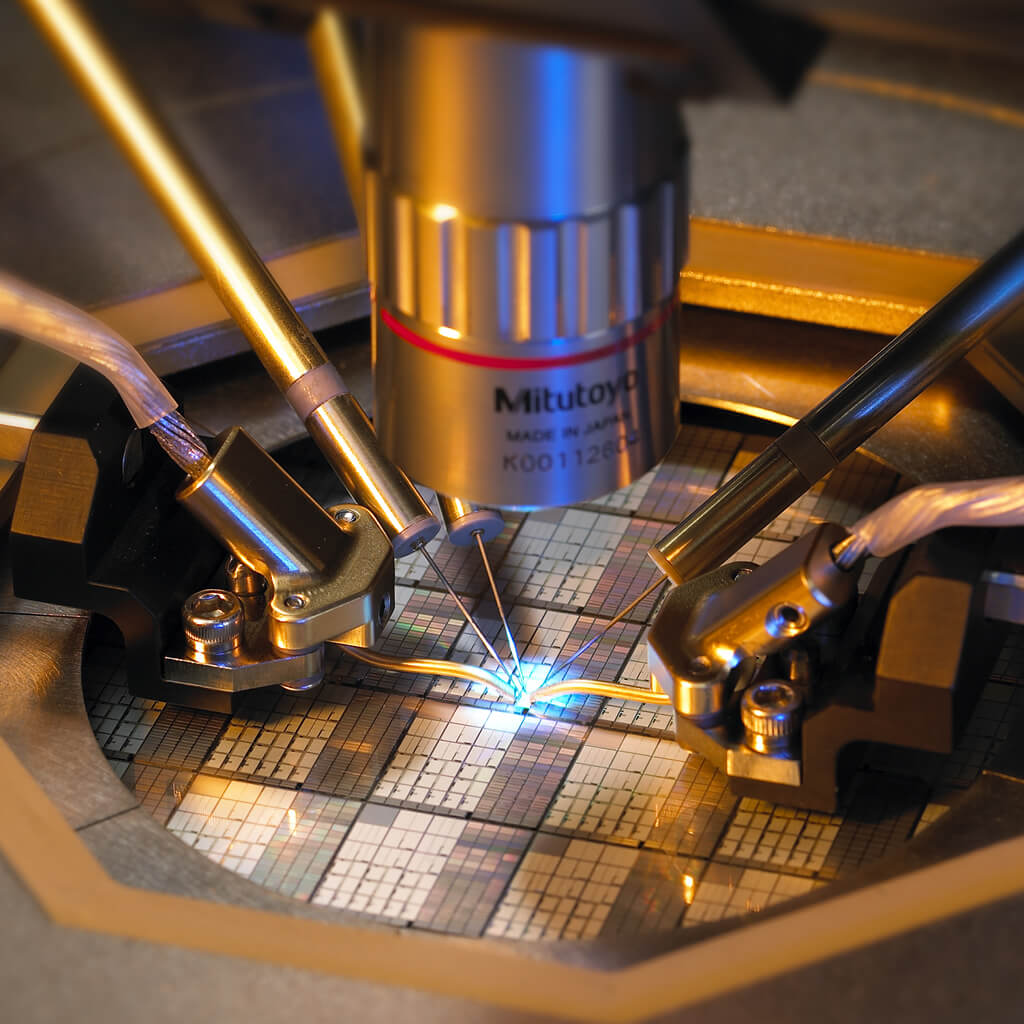

High-voltage/current Probes

|

|

- On-wafer power device characterization up to 10,000 V DC / 600 A

- Reduced probe and device destruction at high currents up to 20 A DC and 300 A pulse

- Increased isolation resistance and dielectric strength to provide full triaxial capability at high voltage (3,000 V) for low-leakage measurement

|

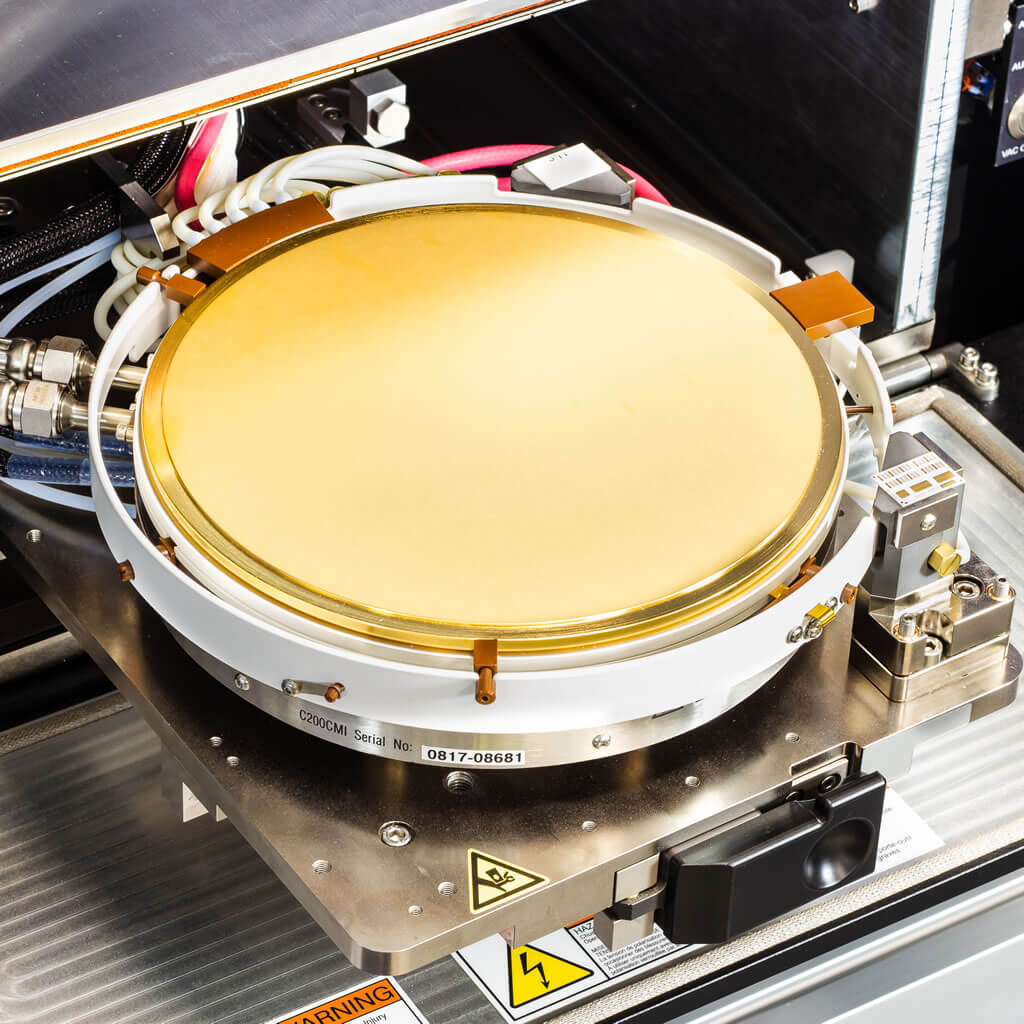

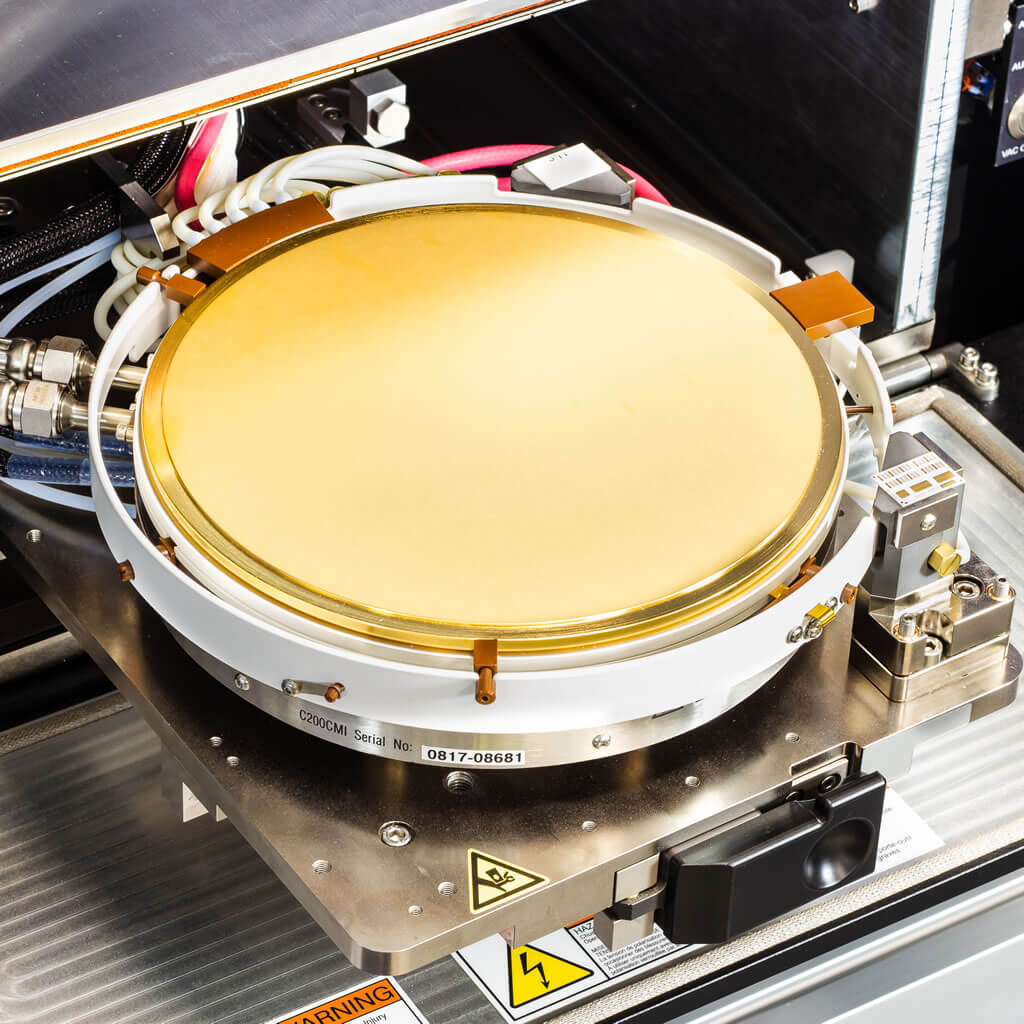

Gold-plated TESLA High-power MicroVac™ Chucks

- Prevent thin wafers from curling and breaking

- Advanced MicroVac chuck surface for minimum contact resistance between wafer and chuck

- Accurate Rds(on) measurement at high current

- Accurate UIS measurements at high temperature

|

|

|

|

|

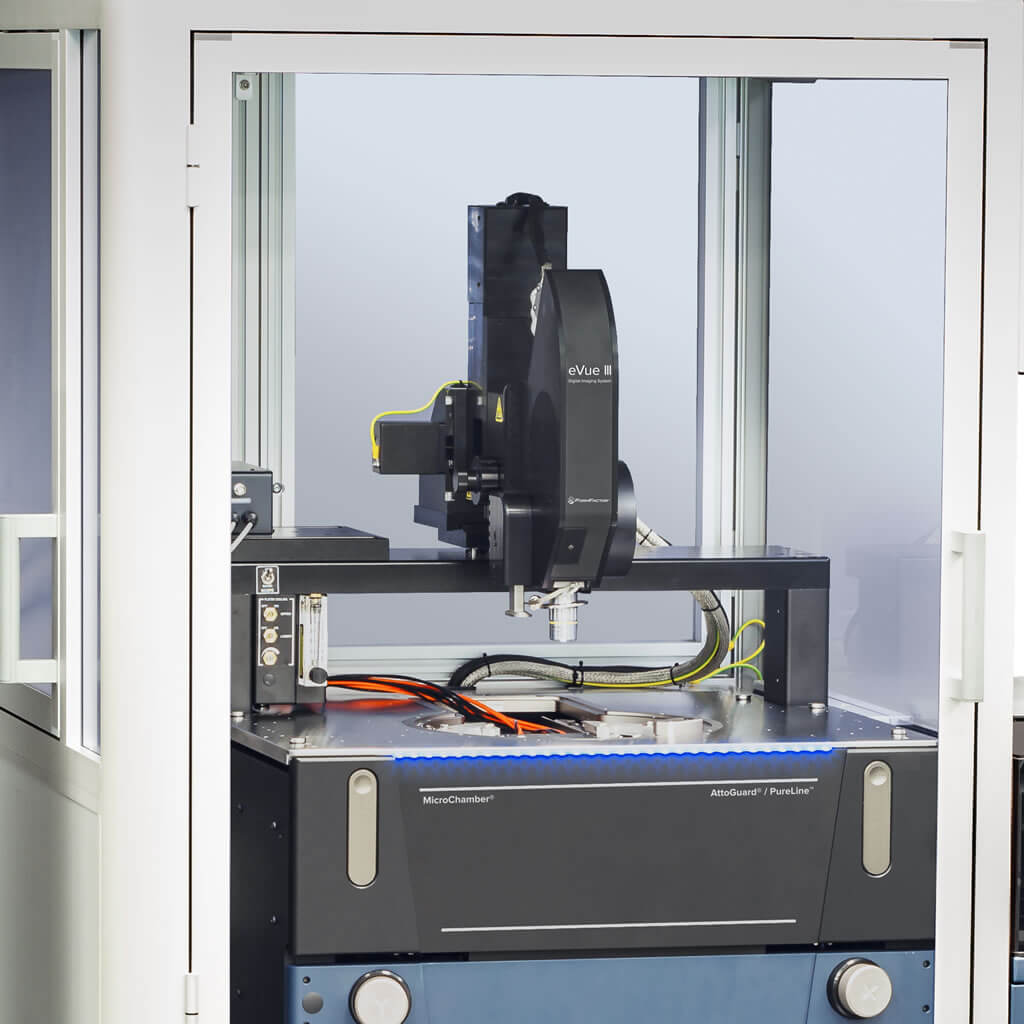

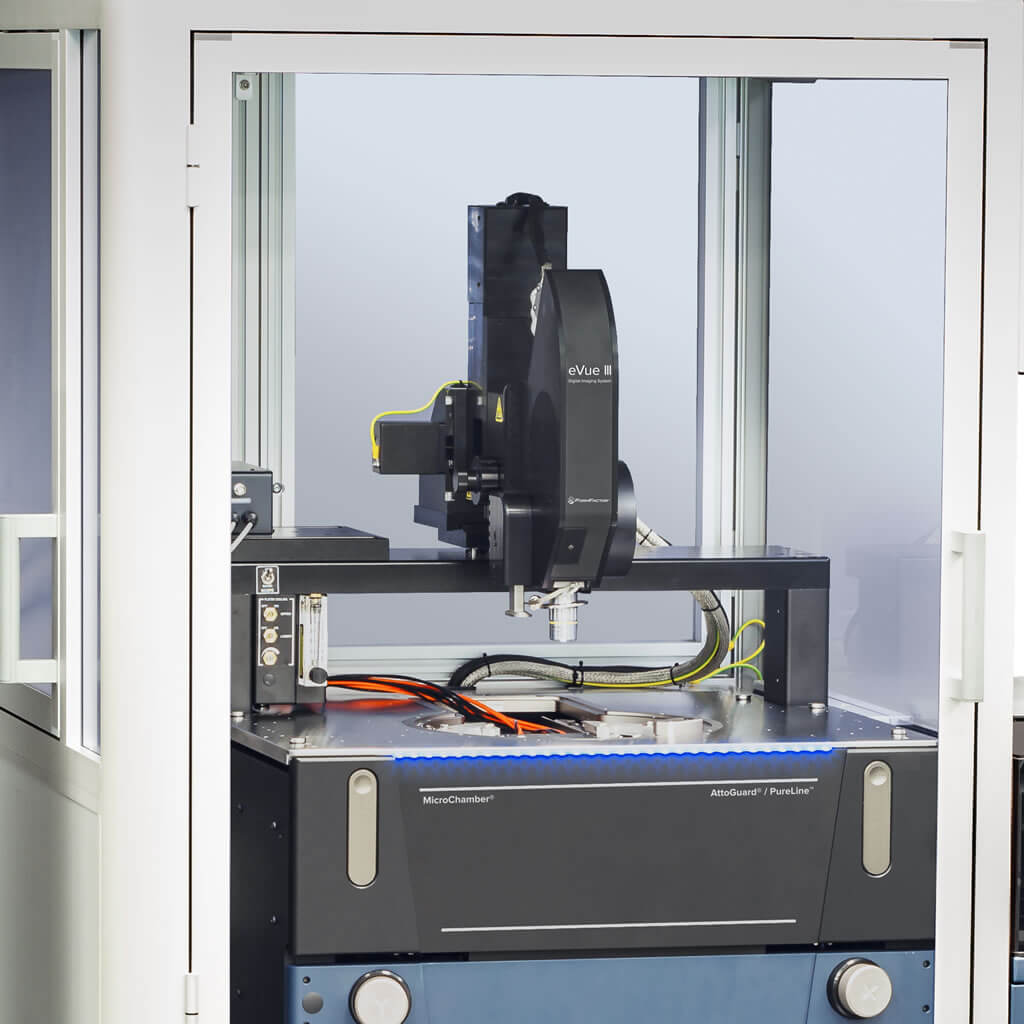

Safety for Operator

- Safety interlock system with clear enclosure for operator safety during device measurements

- Roll-out stage for full wafer access and easy wafer loading/unloading

|

Seamless Integration

- Convenient connection kits for easy and safe system integration with power device analyzers from Keysight Technologies and major suppliers

- Seamless integration between Velox and analyzers/measurement software

|

|

|

|

|

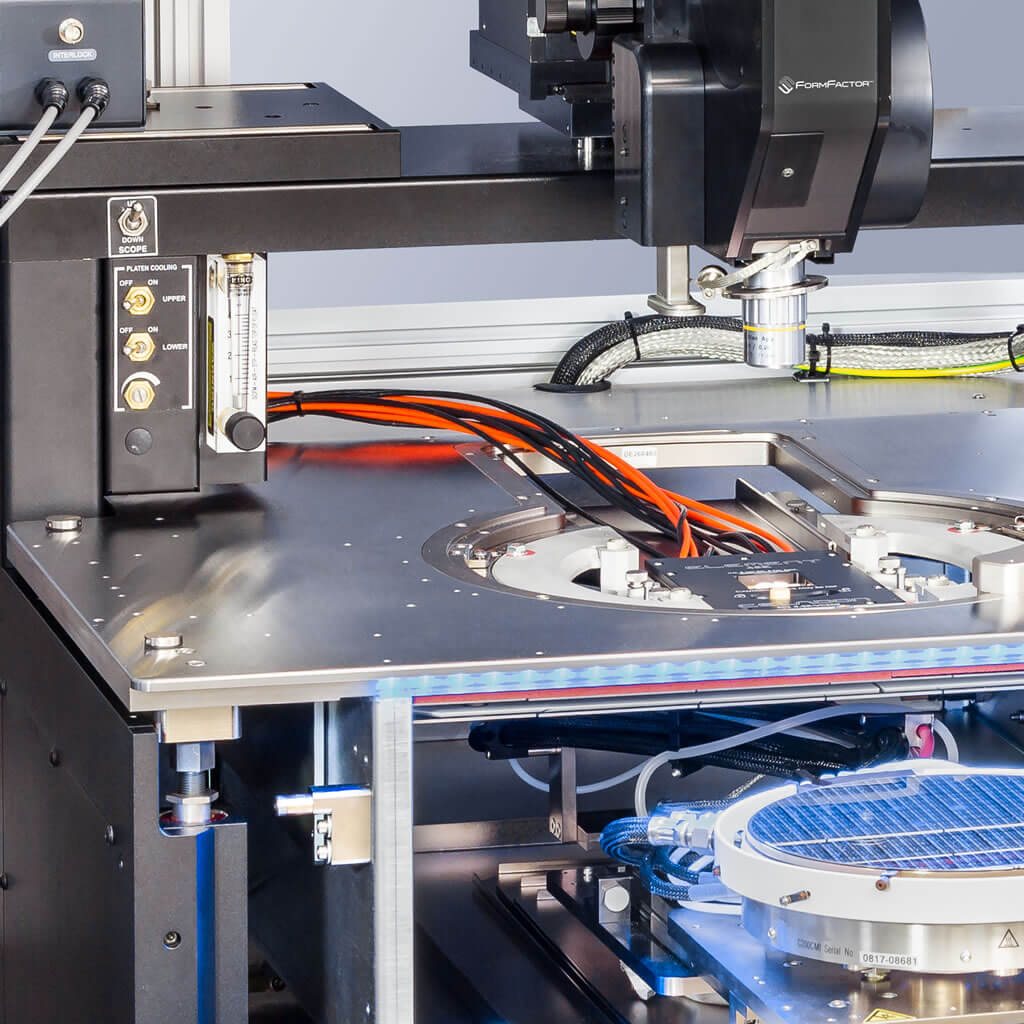

Productivity

- High-throughput wafer autoloading (standard, thinned, warped, TAIKO)

- Contact Intelligence enables higher yield, accurate Rds vertical device measurements over temperature automatically

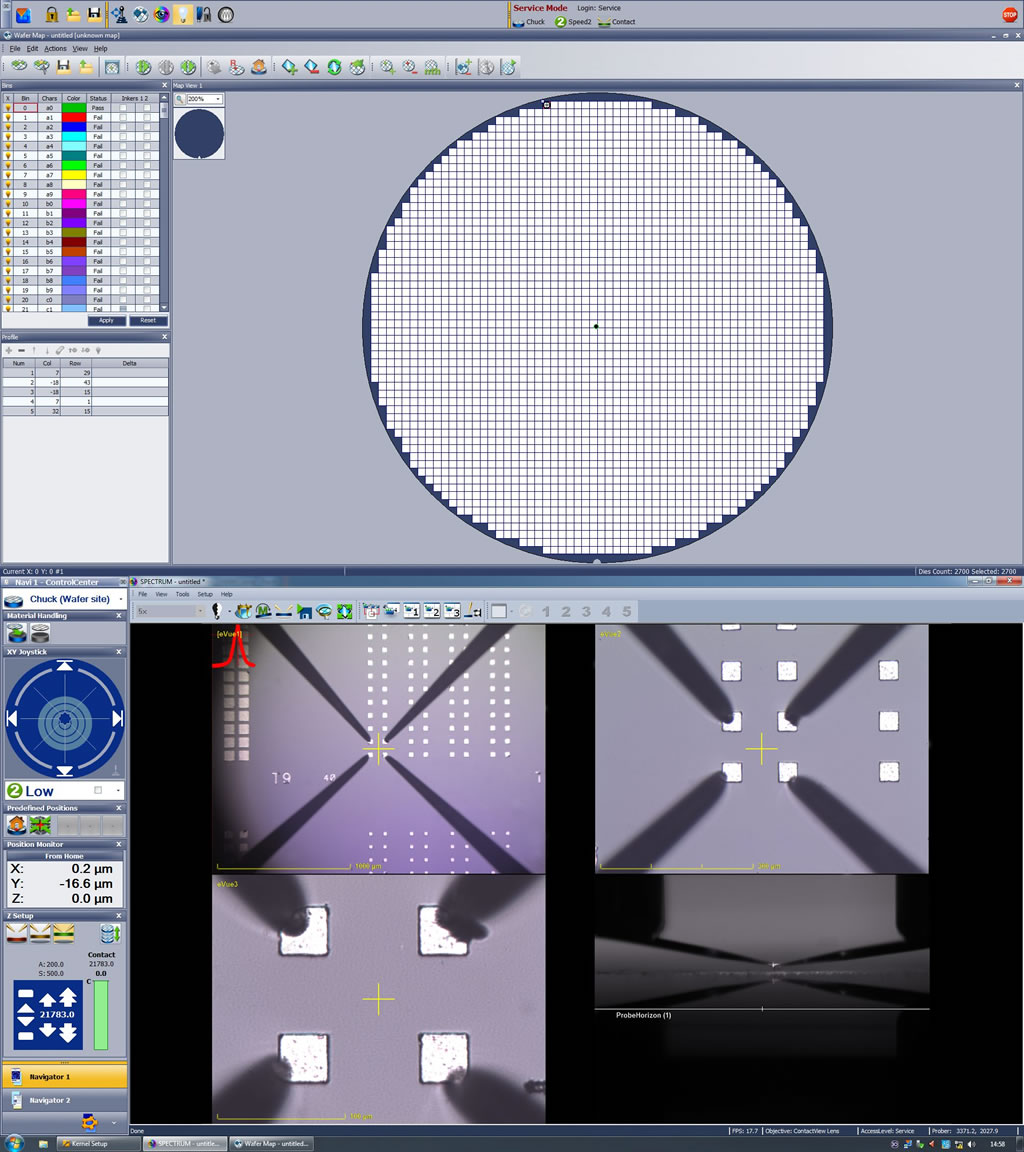

- Easy on-screen navigation, wafer mapping, and operation of accessories with Velox

|

|

Cascade TESLA200 automated wafer power device characterization.