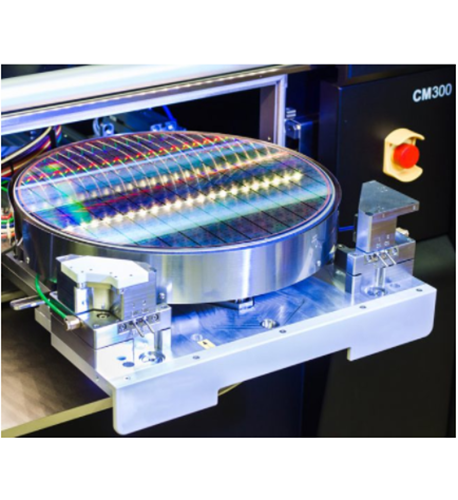

FormFactor Cascade Chucks Non-thermal and thermal chucks

- Flexibility

- Temperatures range from -60°C to +300°C

- Surfaces are nickel or gold-plated

- Hybrid chuck design – operation with and without cooling unit

- Field-upgradeable: On-site cold upgrades for all main prober platforms

- Highest Efficiency for Reduced Cost of Test

- Up to 25% lower air consumption (CDA) than other systems on the market with no compromise in transition times

- Up to 15% faster transition times than other systems on the market

- Low Thermal Resistance

- Low Thermal Resistance Technology

- MultiSense with multiple temperature sensors

- Best temperature accuracy and uniformity

- Superior Electrical Performance

- Isolated from ground

- Includes a jack for grounding and biasing

- Highly planar chuck surface for consistant contact force and overtravel

Introducing the FormFactor Cascade Chucks Non-thermal and thermal chucks

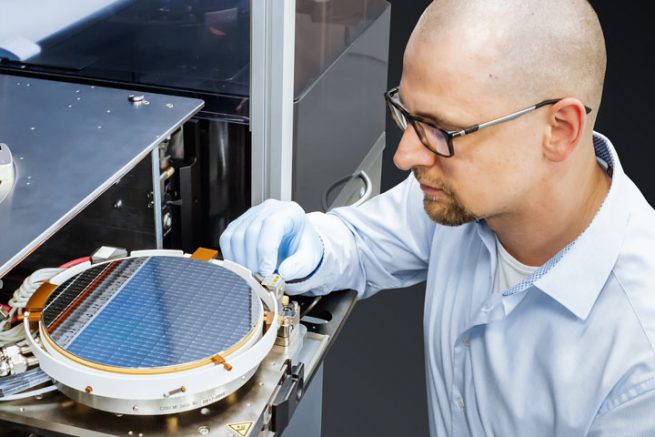

Chucks and Thermal Systems

All FormFactor wafer probe stations are fully integrated with an exclusively developed non-thermal chuck or a highly-reliable thermal chuck system from ATT. Depending on your application, temperature range and performance requirements we offer a large variety of thermal systems from -60°C to 300°C, ranging from the most powerful and fastest high-performance systems in the market to extremely economic systems providing the best cost-performance ratio you can get.

All our systems are nickel or gold-plated and guarantee superior electrical performance. Our patented MicroVac™ and FemtoGuard™ technologies provide advanced measurement accuracy and ultra-low wafer contact resistance, even for warped/thin wafers.

The modular concept for convenient and cost effective system upgrades provides highest safety of investment and easy customization.

Key Features

Flexibility

- Application flexibility: Coax, Triax, RF/mmW, High Power, Double Sided

- Temperatures range from -60°C to +300°C

- Surfaces are nickel or gold-plated

- Hybrid chuck design – operation with and without cooling unit

- Field-upgradeable: On-site cold upgrades for all main prober platforms

Highest Efficiency for Reduced Cost of Test

- Up to 25% lower air consumption (CDA) than other systems on the market with no compromise in transition times

- Up to 15% faster transition times than other systems on the market

Low Thermal Resistance

- Low Thermal Resistance Technology

- MultiSense with multiple temperature sensors

- Best temperature accuracy and uniformity

Superior Electrical Performance

- Isolated from ground

- Includes a jack for grounding and biasing

- Highly planar chuck surface for consistant contact force and overtravel

Patented MicroVac™ Technology

- Advanced wafer vacuum system for warped/partial thin wafers

- Provides uniform vacuum across the entire wafer surface

- 495 micro-holes with 200 µm diameter patterned throughout the chuck

- Five user selectable vacuum zones: even partial wafers that do not cover all the chuck vacuum holes are held down with uniform vacuum

- Increased measurement accuracy with uniform device heat dissipation and ultra-low wafer contact resistance

Patented FemtoGuard™ Technology

- Advanced shielding technology

- Enables ultra-low noise, fully guarded measurements and controlled leakage

- Low residual capacitance for repeatability and advanced measurement accuracy and speed

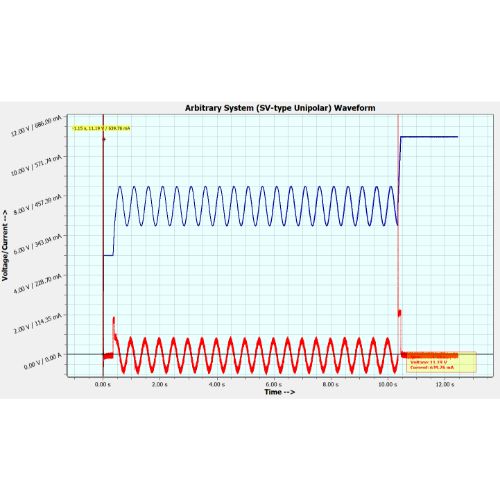

IntelligentDry Air Control

- Active CDA purge control to reduce the dry air consumption

Auxiliary Chucks

- Dedicated RF chucks come with up to three auxiliary chucks for holding calibration substrates and/or cleansing pads

- Different materials available: Steel, Absorber, Ceramic

Key Benefits

Besides our technology-leading coaxial and triaxial chuck systems, our portfolio is complemented with the following specialized chucks:

- RF/microwave chucks, equipped with up to three auxiliary chucks for holding calibration substrates and/or cleansing pads

- High-power chucks with Taiko wafer handling capability, an anti-arcing solution and an auto-discharging system for high throughput and measurement accuracy, while providing a regulatory-certified safe testing environment

- Double Side Chucks: Patented double side design can be configured to hold a variety of different substrate designs and sizes. Mainly used within emission microscopy systems, it can also be used to hold special substrates including MEMS dies held in square metal carriers.

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

Full Thermal Range Systems (-60°C to 300°C)

- Most powerful and fastest high-performance systems for highly demanding requirements

- Shortest transition times in the market

- Optional ECO Mode for lower air consumption (CDA) than other systems in the market (365l/min)

Economic Thermal System (-40C° to 300°C)

- 25% lower air consumption (CDA) than other systems in the market (300l/min)

- Power Mode: 15% faster transition times than other systems in the market

- Best cost-performance ratio of systems with a wide thermal range

Hot-Only Systems (+20°C/+30°C to 300°C)

- Modular and field-upgradeable to cold (-40°C or -60°C): grows with your needs

- Controlled Ambient Technology (+20°C): Precise temperature control, even below ambient temperatures, with no need of an additional chiller

Datasheet