FormFactor Cascade PMC200 200 mm manual cryogenic probe system

- Superior Mechanics

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Use with liquid nitrogen or helium, depending on the target temperature

- Stability

- Independently cooled cold shield

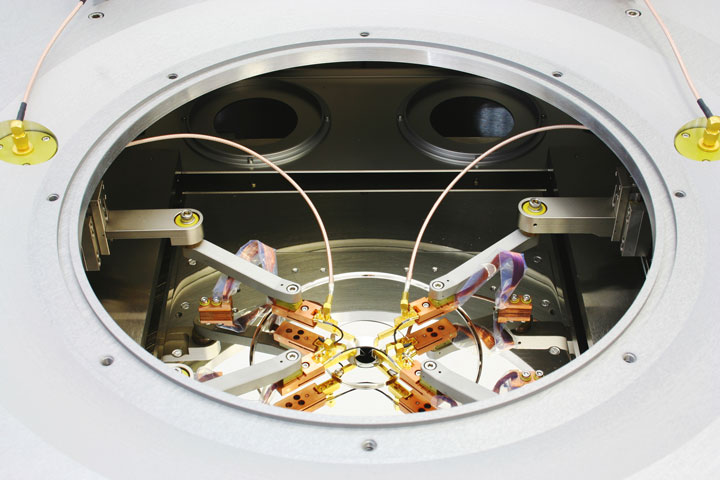

- Probe positioners placed inside vacuum chamber

- Short and stable probe arms

- Solid station frame with built-in vibration-isolation

- Optional microscope bridge

- Optional upgrade for 300 mm wafer

- Ease of Use

- Intuitive, manual drives

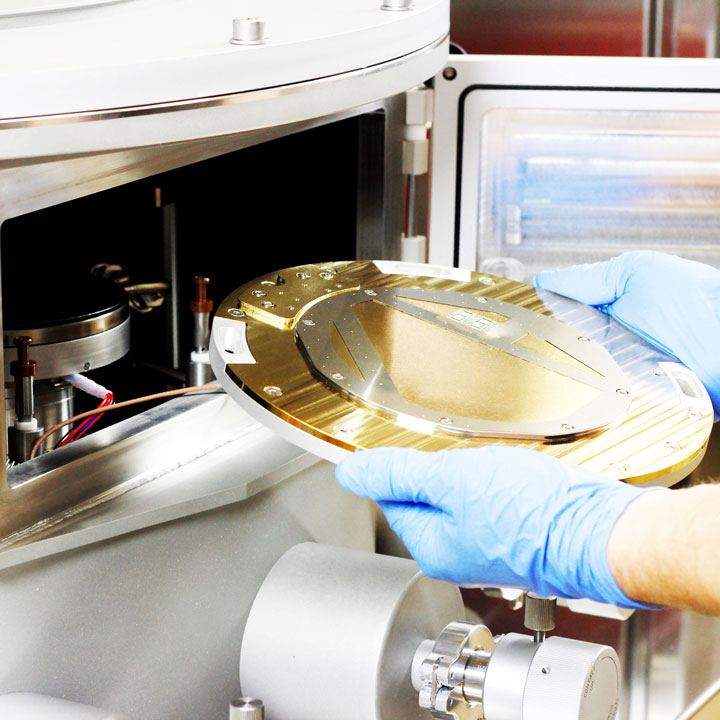

- Front loading capability through load door

- Comfortable and easy operation

- High measurement throughput

- Independent control of linear chuck stage and positioners

- Contact/separation stroke for chuck

- Fast, manual step-and-repeat testing of the whole wafer

Introducing the FormFactor Cascade PMC200 200 mm manual cryogenic probe system

Cascade PMC200 probe system from FormFactor is the ideal solution for testing wafers and substrates up to 200 mm in a cryogenic environment. Specially designed for laboratory requirements, it supports a wide range of measurements, including I-V, C-V and RF, and can be used for probing down to 77 K with liquid nitrogen or 7 K with liquid helium. Application flexibility is ensured for DC and RF measurements of the latest silicon, compound semiconductor and superconductor devices.

The base of the PMC200 is a vibration isolated mainframe. The chuck and the chuck stage with 200 mm x 200 mm X-Y travel, theta and separation stroke are located inside the high-vacuum chamber that contains flanges for vacuum-tight mechanical feedthrough drives. Thus the chuck and up to eight vacuum-type positioners can be easily operated from outside of the chamber via cardan shaft. The high-vacuum pump stand with turbo-molecular-pump (TMP) ensures ice- and condensation-free probing.

To reduce heat entrance, probes are cooled by flexible copper braids connected with the cryo shield. A high-resolution video microscope with 50 mm x 50 mm travel range is mounted either on a microscope bridge for vibration-sensitive test instruments or on a remote controlled lift.

The PMC200 can be customized with various instruments, such as various video microscopes, laser cutters and optical topology measurement tools, or black bodies for exposure of the DUT with controlled IR radiation.

Key Features

Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Use with liquid nitrogen or helium, depending on the target temperature

- Accessories available, such as black bodies and optical motion analysis tools

- Designed for industrial environments

- Covers wide range of measurements (I-V, C-V, RF, MEMS, OPTO)

Stability

- Independently cooled cold shield

- Probe positioners placed inside vacuum chamber

- Short and stable probe arms

- Solid station frame with built-in vibration-isolation

- Optional microscope bridge

- Optional upgrade for 300 mm wafer

- Ice- and condensation-free probing down to 77 K (liquid nitrogen) or below 7 K (liquid helium)

- Precise probe positioning

- Excellent measurement accuracy and repeatability

- Superior vibration attenuation

- Stable image quality for high-resolution microscopes

Ease of Use

- Intuitive, manual drives

- Front loading capability through load door

- Comfortable and easy operation

- Quick and ergonomic change of DUT

High measurement throughput

- Independent control of linear chuck stage and positioners

- Contact/separation stroke for chuck

- Fast, manual step-and-repeat testing of the whole wafer

- Simultaneous contacting and separation of all probes

Key Benefits

| Flexibility | •Customized to meet users’ requirements • Different substrate carriers for wafers up to 200 mm or single dies •Cooling sequence of chuck and shield controlled by cold valves • Use of both, LN2 and LHe •Wide range of measurements (I-V, C-V, RF) •Accessories available, such as laser cutters and optical motion analysis tools |

| Stability | •High accuracy, ideal for small structures •Highly stable mechanics, stable vibration isolation table |

| Ease of use | •Simple, straightforward design for easy and ergonomic operation •Quick and ergonomic change of the DUT through front door |

| High measurement throughput | •Independent control of chuck and positioners for fast step-and-repeat testing of the whole wafer •Platen lift (up and down” for simultaneous separation of all probes |

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

| Chuck Stage | |

| Travel range | Up to 200 mm (round or square) |

| Resolution | 5 µm |

| Manipulation | Linear, from outside the chamber via rotary feed thru drives |

| Probe Platen | |

| Platen space | Universal platen for up to six VCP110 positioners |

| Z contact / separation | About 250 µm |

| Manipulation | From outside the chamber |

| Microscope | |

| Travel | Swivel mechanism for moving the microscope in a safe rest position for chamber opening |

| Focus | Manual drive |

| Type | Video zoom microscope |

| Zoom | 7x |

| Magnification | 0.38x to 2.6x |

| Resolution | 721 lp/mm to 240 lp/mm |

| Field of view | 12.8 mm x 17.1 mm to 1.8 mm x 2.4 mm |

| Chuck | |

| Standard Chuck | No temperature control, holds carrier for fixing single chips, wafer fragments and full wafer up to 150 mm |

| Thermal Chuck | |

| Minimum temperature | -60°C, -40°C, 25°C |

| Maximum temperature | 200°C, 300°C |

| Vacuum Chamber | |

| Size | Approximately ø 600 mm x 300 mm (H) |

| Material | Stainless steel |

| Loading | Hinged top side lid, made of aluminum, fast lock mechanism |

| View port | Central, top side, made of ø 90 mm quartz glass, 6 mm thickness, ø 75 mm clear opening, minimum objective working distance 75 mm |

Datasheet