Key Benefits

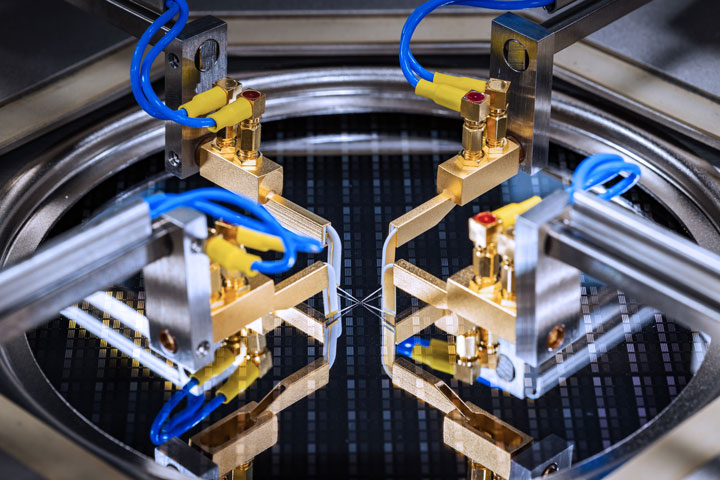

FormFactor’s new CM300xi-ULN (Ultra Low Noise) is a revolutionary 300 mm wafer probing system designed for highly accurate flicker noise (1/f), random telegraph signal noise (RTN or RTS), and phase noise measurements of ultra-sensitive devices.

With the newly patented PureLine™ 3 technology, the ULN probing system enables up to 32x lower noise (1 kHz), for improved device characterization and modelling at the 7/5/2 nm technology nodes targeted for 5G and beyond applications. By eliminating over 97% of the environmental noise experienced in previous probe systems, the CM300xi-ULN system establishes a new industry gold standard for ultra-low noise measurements.

When integrated with noise test equipment (flicker noise, RTN, phase noise), the CM300xi-ULN offers the industry’s highest test throughput, using Contact Intelligence™ with motorized probe positioners, enabling fully Autonomous DC and low frequency noise probing with multi-DUT layouts for complete hands-free 24/7 operation.

Finally, the CM300xi-ULN takes the complexity out of low noise TestCell optimization. Just plug it in and go. TestCell Power Management eliminates all ground-loop induced TestCell noise and provides fully managed and filtered AC power to the entire system, prober and instruments.

Additionally, FormFactor’s exclusive low-noise Site Survey and System Verifications significantly reduce setup costs and tool deployment time. This allows lab engineers to focus on getting good device data, that can be used to reduce the number of costly re-designs and accelerate time to market with lower development costs.

* Typical noise (dBVrms/√Hz, 1kHz to 1MHz), with prober and thermal system enabled.

Applications: Flicker Noise (1/f), Random Telegraph Noise (RTN), and Phase Noise Measurements of Ultrasensitive Devices