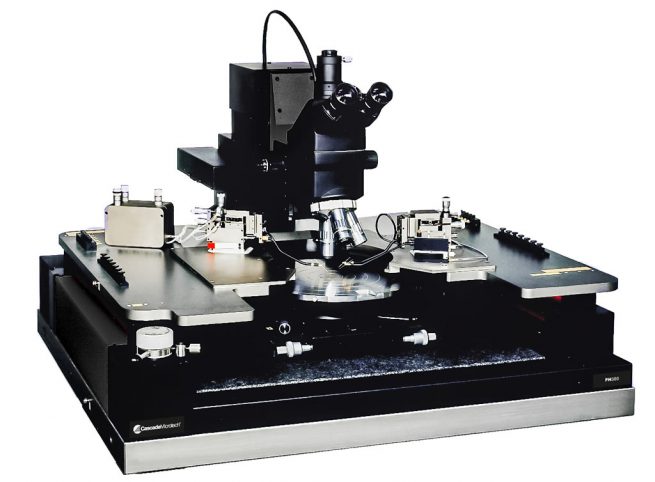

FormFactor Cascade PM300 300 mm manual probe system

- Superior Mechanics

- Highly stable granite base

- Fast navigation and high-precision probe positioning

- High Flexibility

- Re-configurable for DC, RF, mmW, FA, WLR and more

- Full thermal range of -60°C to +300°C

- Ease of Use

- Low-profile, straightforward design

- Spacious top chambers for up to 12 positioners

- Easy and ergonomic operation

- Shielding

- Reduces electrical noise by providing a fully electromagnetically shielded, ultra-low-noise, light-tight environment

- Full thermal range of -60°C to +300°C available

Introducing the FormFactor Cascade PM300 300 mm manual probe system

Cascade PM300 probe system from FormFactor is the ideal solution for engineering tests of 300 mm wafers and substrates. Whatever your application, the versatility of the PM300 meets all requirements from failure analysis (FA) to device and wafer characterization (DWC) to wafer-level reliability (WLR) testing and always ensures the highest accuracy. With the optional square chuck, the PM300 can be also used for testing of flat panel displays.

The superior mechanics of the probe system are the basis for stable and precise system setup regardless of your application. The X and Y axes of the chuck stage can be moved easily and individually for fast coarse adjustment. Each axis has been designed with an individual magnetic lock and a vacuum brake that enables the fine glide chuck stage to be exactly positioned whenever you release the button. Fine adjustment is ensured for X and Y by high-precision micrometers.

The PM300 has been designed with the user in mind. You can start out with the basic setup of the PM300 and the system is scalable to meet your expanding test requirements. For example, light-sensitive measurements in a ShieldEnclosure™,thermal chucks or various high-frequency test setups up to mmW are available. Further flexibility is achievable with motorized probe positioners.

Key Features

Superior Mechanics

- Highly stable granite base

- Independent, coarse movement of X and Y axes, combined with easy fine adjustments

- Excellent measurement accuracy and repeatability

- Fast navigation and high-precision probe positioning

High Flexibility

- Re-configurable for DC, RF, mmW, FA, WLR and more

- Full thermal range of -60°C to +300°C

- Multiple accessories: Thermal chucks, motorized microscopes and positioners, dark box, and more

- 40 mm platen height adjustability

- Upgrade path to meet your future needs

- Fast transition between wafer and packaged device test

Ease of Use

- Low-profile, straightforward design

- Spacious top chambers for up to 12 positioners

- Easy and ergonomic operation

Shielding

- Reduces electrical noise by providing a fully electromagnetically shielded, ultra-low-noise, light-tight environment

- Enables accurate low-noise measurements of atto amperes, femtofarads and microvolts at temperatures down to -60°C

- Ideal conditions for sensitive applications such as 1/f noise measurements

- Full thermal range of -60°C to +300°C available

Key Benefits

| Flexibility | • Flexible design for engineering tests •Easy changeover between different applications •Ideal for failure analysis, DWC and WLR applications •Wide range of accessories available, for example ShieldEnclosure SE1200 •Thermal chucks (only hot) and motorized microscope available |

| Stability | •Superior mechanics for highest degree of stability |

| Ease of use | •Quick and easy system set up •Independent, coarse movement of X and Y axes •Easy fine adjustments through high-precision micrometers located on frontside of chuck stage •Independent magnetic locks and vacuum brakes for X and Y axes •Ergonomic low-profile design |

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

| Chuck Stage | |

| Range of movement | X, Y, theta |

| Coarse adjustment | 300 mm x 300 mm |

| Planarity of granite slab over entire range of movement | < ± 2.5 µm |

| Load stroke | Standard mode: ≤ 2 µm (0.08 mils), Precision mode: ≤ 0.3 μm (0.012 mils) |

| Speed | 10 mm |

| Theta travel | ± 8° |

| Chuck | |

| Diameter | 300 mm (optional square) |

| Planarity | 8 µm |

| Probe Platen | |

| Z travel | 40 mm |

| Contact / Separation stroke | 0.4 mm |

| Utilities | |

| Power | 115 / 230 V, 50 / 60 Hz |

| Vacuum | – 0.8 bar |

| Compressed air | 6 to 10 bar |

* Data, design and specification depend on individual process conditions and can vary according to equipment configurations. Not all specifications may be valid simultaneously

Datasheet

Hioki POWER METER PW3337

Hioki POWER METER PW3337