FormFactor CM300xi-SiPh 300 mm semi-/ fully-automated probe system

with Autonomous Silicon Photonics Measurement Assistant

- Revolutionary technology advancement for wafer and die-level photonics probing

- Enables autonomous measurements

- Highest accuracy in test results

- Reduced risk of damaging fibers with collision avoidance technology

- Easy setup even for less experienced users

- Minimized coupling losses with minimal trench dimensions

- Positioning hardware is precisely calibrated to the probe station and ready to perform die-to-die optical optimizations in minutes

- Other integrated features: Incident Angle Cal, Optical Rotation Scan, Optical Scan Data Analysis, Optical Tracking, Align Optical Probes

- 40°C to +125°C

- Enables hands-free autonomous calibration and re-calibration at multiple temperatures

Introducing the FormFactor CM300xi-SiPh 300 mm semi-/ fully-automated probe system

CM300xi Overview

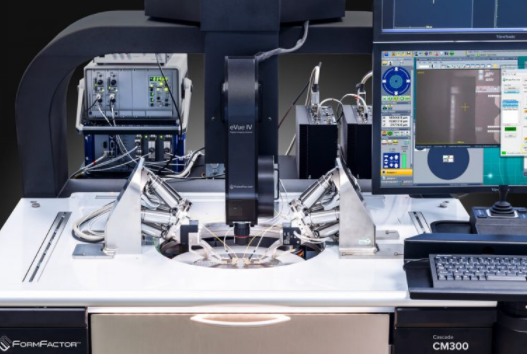

Best-in-class measurement performance at a high level of automation in the lab*

The CM300xi probe station meets the measurement challenges brought on by extremely complex environments, such as unattended testing on small pads over time and at multiple temperatures. Best-in-class measurement performance is achieved for a wide range of applications in an EMI-shielded, light-tight and moisture-free test environment. Thermal management enhancements and lab automation capabilities result in improved yields and faster time to data.

The CM300xi supports Contact Intelligence™ – a unique technology which enables autonomous semiconductor test. A powerful combination of innovative system design and state of the art image processing provides an operator-independent solution to achieve highly-reliable measurement data at any time and temperature.

With the material handling unit, the CM300xi probe station combines fully-automated wafer test with highest accuracy and flexibilty. The system can handle up to fifty 200 or 300 mm wafers provided in SEMI-standard wafer cassettes

Key Features

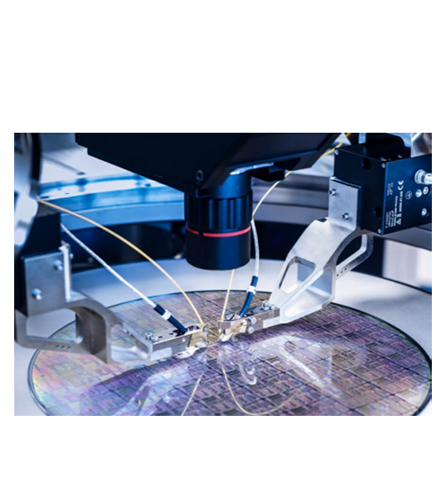

OptoVue

- Revolutionary technology advancement for wafer and die-level photonics probing

- Real-time in-situ calibrations

- Singulated die testing

- True die-level edge coupling

- In-situ power measurements

- Advanced calibration technologies

- Enables autonomous measurements

Horizontal Die-Level Edge Coupling

- Highest accuracy in test results

- Lowest coupling loss

- Repeatable measurement results due to exclusive automated fiber-to-facet alignment technology

- Reduced risk of damaging fibers with collision avoidance technology

- Ease of use for less experienced users

- Enables close simulation of real-world conditions with device performance closest to the final application

Wafer-Level Edge Coupling

- New innovative combination of hardware and software features to align and optimize fibers/arrays in a wafer-level trench

- Minimized coupling losses with minimal trench dimensions

- Easy setup even for less experienced users

- Repeatable measurement results due to unique fiber-to-facet gap alignment technology

- Reduced risk of damaging fibers with collision avoidance technology

Vertical Coupling

- Industry standard for vertical coupling to wafer-level grating couplers

- Positioning hardware is precisely calibrated to the probe station and ready to perform die-to-die optical optimizations in minutes

- Exclusive Pivot Point calibration determines the optimal point of minimal translation at the fiber/array tip

- Search First Light feature enables automated determination of initial position for optimization

- Other integrated features: Incident Angle Cal, Optical Rotation Scan, Optical Scan Data Analysis, Optical Tracking, Align Optical Probes

Key Benefits

| OptoVue Pro | •Real-time in-situ calibrations, singulated die testing, true die-level edge coupling, in-situ power measurements, dvanced calibration technologiessystem |

| Edge Coupling | • Repeatable measurement results due to exclusive automated fiber-to-facet alignment technology • Reduced risk of damaging fibers with collision avoidance technology • Horizontal die-level edge coupling: lowest coupling loss and highest accuracy in test results • Wafer-level edge coupling: innovative technology aligns fibers/arrays in a wafer-level trench |

| Automated test | Contact Intelligence enables unattended tests on small pads •Thermally induced drift can be automatically corrected, enabing automated temperature transitions over the full temperature range using VueTrack or ReAlign (the effective temperature range and minimum obtainable pad size depend on probe card and probe card holder or positioner used) |

| Vertical Coupling | Industry standard for vertical coupling to wafer-level grating couplers • Pivot Point calibration determines the optimal point of minimal translation at the fiber/array tip • Search First Light feature enables automated determination of initial position for optimization • Incident Angle Cal, Optical Rotation Scan, Optical Scan Data Analysis, Optical Tracking, Align Optical Probes |

| Thermal Capability | Dark, shielded and frost-free, -40°C to +125°C • Only solution available that enables minimized air flow impact at cold temperatures to the fibers/fiber arrays for stable and repeatable measurement results • Enables hands-free autonomous calibration and re-calibration at multiple temperatures |

| Exclusive Automated Calibrations |

• Pioneering set of automated functions that perform critical calibrations of the optical positioning system to the probe station • Faster time to measurement and reduced cost of test with real-time in-situ automated calibrations • Further exclusive calibration functions: motor calibration, Z-displacement calibration, theta calibrations, PZT calibration, planarity calibrations, automatic pivot point calibration |

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

| X-Y Stage | |

| Travel XY | 301 mm x 501 mm (11.9 in. x 19.7 in.) |

| Resolution | 0.2 µm (0.008 mils) |

| Repeatability | ≤ 1 µm (0.04 mils) |

| Accuracy | Standard mode: ≤ 2 µm (0.08 mils), Precision mode: ≤ 0.3 μm (0.012 mils) |

| Speed | 50 mm/sec (2 in./sec) |

| Bearings | Precision balls bearings |

| Motor-drive system | High-performance micro stepper motor |

| Feedback system | Ceramic ultra-low thermal expansion linear encoder |

| Z Stage | |

| Travel | 10.0 mm (.39 in.) |

| Resolution | 0.2 µm (0.008 mils) |

| Repeatability | ≤ 1 µm (0.04 mils) |

| Accuracy | ≤ 2 µm (0.08 mils) |

| Speed | 20 mm/sec (0.8 in./sec) |

| Lifting capacity | 20 kg (44 lb.) |

| Probe-force deflection (measured at the chuck edge) | ≤ 0.0007 µm/µm slope per 10 kg load (0.0007 in./ in./22 lb) |

| Theta Stage | |

| Travel |

± 3.75° |

| Resolution | 0.2 µm (0.008 mils)*; 0.00008° |

| Repeatability | ≤ 1 µm (0.04 mils)*; ≤ 0.0004° |

| Accuracy of fine correction | ≤ 2 µm (0.08 mils)*; ≤ 0.0008° |

| Accuracy of large movement (>2°) | ≤ 5 µm (0.20 mils)*; ≤ 0.0019° |

* Measured at edge of 300 mm chuck

Datasheet