3-Phase 4-Wire Power Quality Analyzer Compliant to IEC61000-4-30 Class S Standards and On-screen Guide to Deliver Easy Setup and Testing

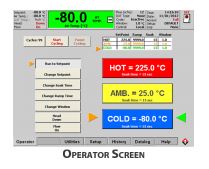

inTEST Thermal Temptronic ECO-710M THERMOSTREAM®

- 20 Amp Operation: Full performance with 20 amp service

- Automatic Power Reduction: Reduces power usage during idle periods

- Heat Only Mode: Reduces power usage when cold temperatures are not used

- WhisperStream Technology: quieter, smooth-sounding operation, 56 dBA

- Frost Free Test Environment: dry air purge for tester interface, prevents condensation:

0.5 to 3scfm (0.25 to 1.5 l/s) - Heated Defrost: quickly removes moisture buildup from internal chiller

- DUT Temperature Control : Proprietary control algorithm enables DUT temperature to be directly controlled

- Transition Rate*

-55 to +125°C, approx. 10 seconds

125 to -55°C, approx. 10 seconds - System Airflow Output*

4 to 18scfm (1.9 to 8.5 l/s) Continuous - Temperature Range*

-80 to +225°C (60Hz) No LN2 or LCO2 Required

Introducing the inTEST Thermal Temptronic ECO-710M THERMOSTREAM®

Eco-friendly Electronics Temperature Test Systems

Consumes less energy, quiet operation, no annual leak testing required (EU F-Gas Regulation)

The ECO Series is an environmentally friendly Temptronic® ThermoStream® temperature forcing system that uses less energy with ECO series thermal test system very low audible noise. The temperature test system operates on a low, 20-amp circuit and incorporates the company’s proprietary technology providing quiet, smooth-sounding operation at 56 dBA. The ECO-710 and ECO-810 are designed for 24/7/365 day use in production or lab environments where audible noise, heat dissipation, and energy usage are of concern.

Furthermore, the ECO system frees you from the time and expense of annual leak testing because its gas charge is below the CO2 equivalent limit for greenhouse gas emissions as specified in the EU 517/2014 regulation. After 2016, all refrigeration systems shipped to EU countries, portable and stationary, will require labeling of gases used, their weight, and CO2 equivalent. Any refrigeration system with a charge of 10 tonnes or greater will require annual leak checking.

- Precise temperatures with fast transitions from -80 to 225°C

- No annual leak testing required per EU 517/2014 F-Gas Regulation

- Effective testing and conditioning of electronic components, boards, and modules

- Available for 50 and 60Hz operation

- No need for Liquid Nitrogen (LN2) or Liquid Carbon Dioxide (LCO2)

- Remote communications and set up and touch screen operation

Key Features

ECO-710M ThermoStream®

Temptronic® ECO Series temperature forcing systems use less energy with very low audible noise. Operate on a low, 20-amp circuit and incorporate the company’s proprietary WhisperStreamTM technology for quiet, smooth-sounding operation at 56 dBA. Designed for environments where noise and heat dissipation are of concern, and meets the EU F-Gas regulation where no annual leak testing is required.

Power Requirements

200 – 250 VAC (230V nominal), 50/60Hz, 20 amp, 1phase

Transition Rates

Heating: -55 to +125°C, <10

Cooling: +125 to -55°C, <10

Key Benefits

APPLICATION OPTIONS:

- Thermal Cap or FlexExtender Hose :

- 4.5 or 5.5 inch ID Thermal Cap or optional FlexExtender Hose for connection to external Thermal Chambers or enclosures

- MobileTemp™ Thermal Chambers :

- Temperature Chambers designed specifically for use with ThermoStream systems. See Additional Datasheets for details.

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

| Power | 200 – 250 VAC, 60Hz, 20 amp, 1phase |

| COMPRESSED AIR | |

| Compressed Air2 | Clean Dry Air (CDA), filtered to 5 micron particulate contamination. Oil Content: <0.1 ppm, by weight, filtered to 0.01 micron oil contaminant. Dewpoint: <10°C @ 6.2 BAR (90PSI) |

| Air Supply Pressure | 6.2 to 7.6 BAR (90 to 110 PSIG) |

| Total Air Flow Rate Required | 7.1 to 14.2 l/s (15-30 scfm), 11.8 l/s (25 scfm) nominal |

| Air Supply Temperature | +20° to +25°C; +22°C nominal |

| OPERATING ENVIRONMENT | |

| Operating Temperature | +20° to +28°C; +23°C nominal |

| Humidity | 0 to 60%; 45% nominal |

| WEIGHTS & DIMENSIONS | |

| Base3 | Width: 61.0 cm (24 in.), Depth: 72.4 cm (28.5 in.), Height: 108 cm (42.5 in.) |

| System Weight | Not packed: 236 kg (520 lbs.) Packed: 365 kg (805 lbs.) |

| Mobility | Four static dissipative, swivel caster wheels |

| Maximum Reach | 160.0cm (63 in.) |

| Maximum Operating Height | 130.3 cm (51.2 in.) Extended height option: 188.0 (74.0 in.) |

| Minimum Operating Height | 69.1 cm (27.2 in.) Extended height option: 81.3 (32.0 in. |

| Noise Leve | <56 dBA |

| SERVICE & SAFETY | |

| Refrigerants |

HCFC and CFC-free, non-toxic, non-flammable |

| Serviceability | Auto-diagnostics and field replaceable modules |

| Over Temperature Protection | Settable high and low air temperature limits (factory set at +230°C) |

| Compliance | CE, RoHS, EU 517/2014 (<10 tons CO2 eq, no annual leak testing required) |

Datasheet