DC, 0.5 Hz to 200 kHz, 3-phase 4-wire, High Precision Power Analyzer for Motor and Inverter Efficiency Analysis

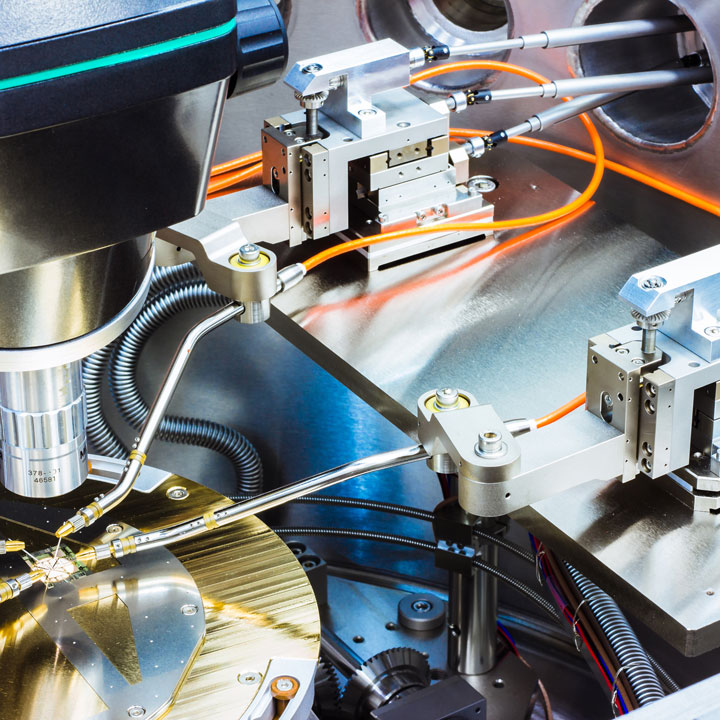

FormFactor Cascade PAV200 200 mm semi-automated vacuum probe system

- Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Optional thermal chuck (-60°C to 300°C) and pressure regulation

- Stability

- Probe positioners placed inside vacuum chamber

- Short and stable probe arms

- Solid station frame with built-in vibration-isolation

- Optional microscope bridge

- Precise probe positioning

- Ease of Use

- Joystick controller

- Manual probe positioners with rotary feed-throughs

- Front loading capability through load door

- Comfortable and easy operation

- High measurement throughput

- Software control of chuck for fast step-and-repeat testing of the entire wafer

- Fast step-and-repeat testing of the whole wafer

Introducing the FormFactor Cascade PAV200 200 mm semi-automated vacuum probe system

The Cascade PAV200 probe system from FormFactor is the ideal solution for automatic testing of wafers and substrates up to 200 mm in a high vacuum environment up to 10-5 mbar. It supports a wide temperature range from -60°C to 300°C.

It supports a wide range of applications, including DC and RF measurements, MEMS and opto-engineering tests. The probe platen is designed to mount probe cards or up to eight vacuum-type positioners on magnetic feet. A high-resolution video microscope with 50 mm x 50 mm travel range is mounted either on a microscope mount with swivel or on a microscope bridge for vibrationsensitive test applications and additional test instruments.

Key Features

Flexibility

- Different substrate carriers for wafers up to 200 mm or single dies

- Probe cards and/or up to eight positioners

- Optional thermal chuck (-60°C to 300°C) and pressure regulation

- Accessories available, such as black bodies and optical motion analysis tools

- Optional upgrade for 300 mm wafer

- Designed for industrial environments

- Covers wide range of measurements (I-V, C-V, RF, MEMS, OPTO)

- Ideal for small structures

Stability

- Probe positioners placed inside vacuum chamber

- Short and stable probe arms

- Solid station frame with built-in vibration-isolation

- Optional microscope bridge

- Precise probe positioning

- Excellent measurement accuracy and repeatability

- Superior vibration attenuation

- Stable image quality for demanding MEMS analysis

Ease of use

- Joystick controller

- Manual probe positioners with rotary feed-throughs

- Front loading capability through load door

- Comfortable and easy operation

- Quick and ergonomic change of DUT

High measurement throughput

- Software control of chuck for fast step-and-repeat testing of the entire wafer

- Fast step-and-repeat testing of the whole wafer

Key Benefits

| Flexibility | • Different substrate carriers for wafers up to 200 mm or single dies • Upstream pressure, downstream pressure or medium vacuum regulation •Velox™ probe station control software •Wide range of measurements (I-V, C-V, two-port, multi-port and differential RF) •RF tests supported by a wide range of probes and calibration tools, such as calibration substrates and WinCal XE™ calibration software •Accessories available, such as Black Bodies and optical motion analysis tools |

| Stability | •High accuracy, ideal for small structures •Highly stable mechanics with a stable vibration isolation table |

| Ease of use | •Simple, straightforward design for easy and ergonomic operation •Quick and ergonomic change of the DUT through front door |

| Automation | •Pressure control: up-stream, down-stream, high-precision capacitance vacuum gauges •Bridge with rails for programmable movement of mounted instruments |

| High measurement | •Automatic control of chuck for fast step-and-repeat testing of the entire wafer throughput |

Trust the Experts at ACA TMetrix Inc.

ACA TMetrix Inc. is a leading Canadian distributor of test and measurement instruments and design tools. For over 55 years we have provided products manufactured by the world’s leading instrument manufacturers. Leading Distributor of Design Tools and Test Equipment in Canada.

Specifications

The PAV200 is equipped with a stable vibration isolating frame. The chuck and the motorized chuck stage with 200 mm x 200 mm X-Y travel, theta and Z-axis are located inside the high-vacuum chamber. Up to eight vacuum-type positioners can be easily operated from outside of the chamber via vacuum-tight mechanical feedthrough drives and cardan shafts. For the use under vacuum conditions, specially-designed thermal chucks with electrical and cooling line bulk-feedthroughs are available.

Datasheet