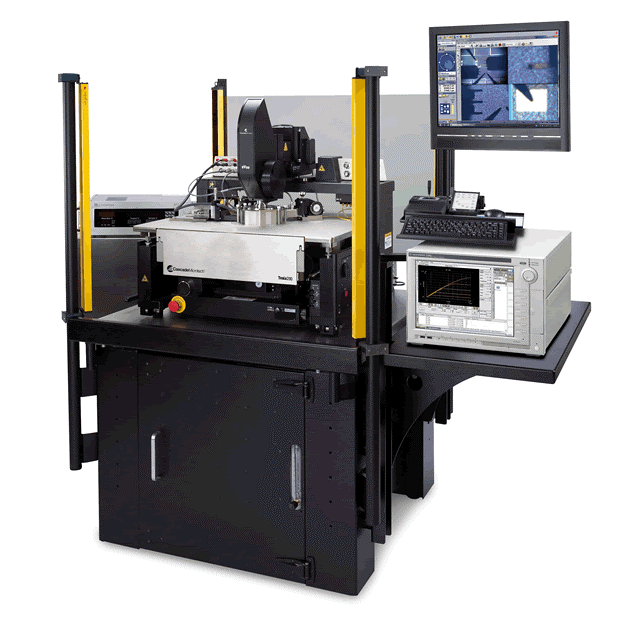

Tesla T200 Overview

The Tesla T200 200mm semi-automatic power device characterization system provides a complete on-wafer solution for over-temperature, low-contact resistance measurements of power semiconductors up to 3,000 V (triax)/10,000 V (coax) and 200 A (pulsed)/10 A (DC). It does this while providing a low-noise, fully guarded and shielded test environment, as well as a certified safety interlock system integrated with an ergonomic clear enclosure or infrared laser light curtain.

Tesla T200 Key Features

|

|

Seamless integration

- Convenient instrument connection kits

- Seamless integration between Velox and analyzers/measurement software

- Easy and safe system integration with Keysight and Keithley power device analyzers

|

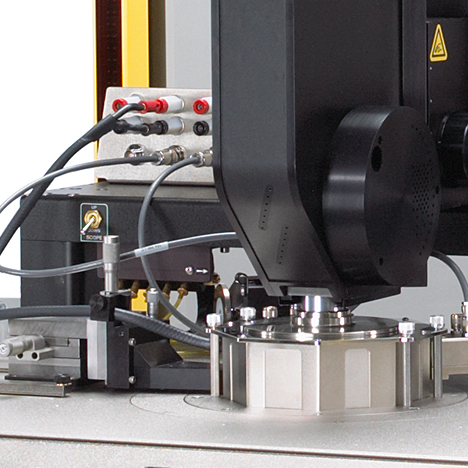

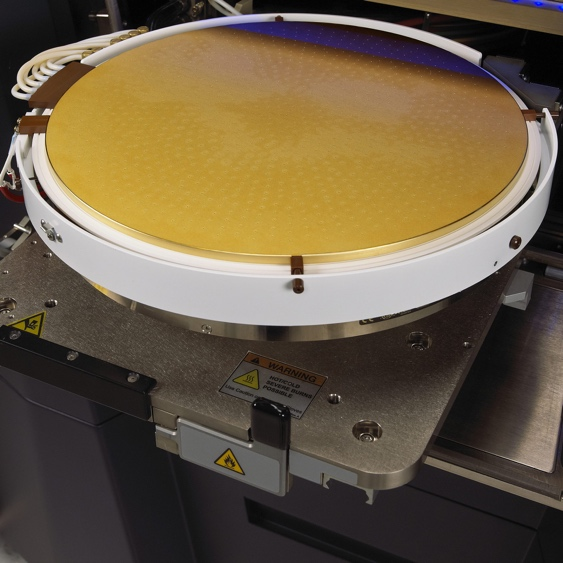

MicroVac™ chuck

- 495 uniformly distributed vacuum micro-holes

- Gold-plated, high-power chuck surface

- Thin-wafer handling capability

- Low electrical and thermal contact resistance across the entire wafer

- Prevents thin wafers from curling and breaking

|

|

|

Safety

- Regulatory-certified probing environment

- Safety interlock system with clear enclosure or light curtain

- Fully guarded and shielded test environment

- Operator safety during measurements

- Protects device and instrumentation from high-voltage discharge

|

Ease of use

- Roll-out stage

- Full wafer access and easy wafter loading/unloading

|

|

|

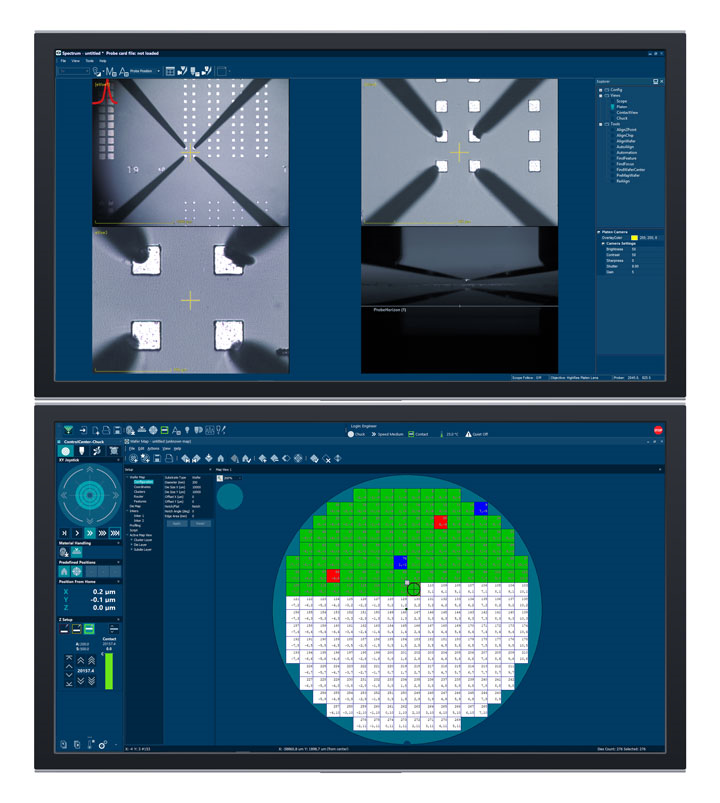

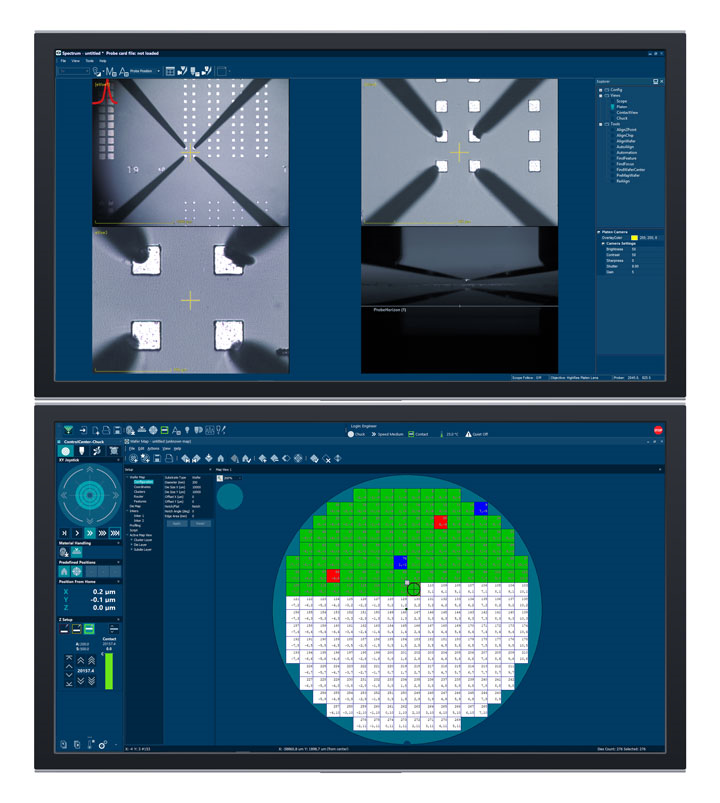

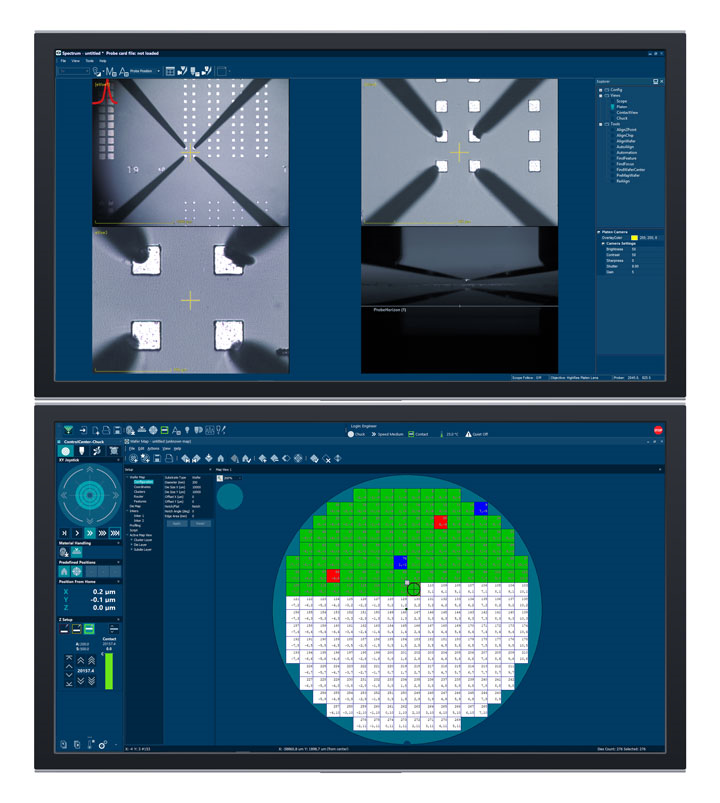

Velox probe station control software

- User-centered design minimizes training costs, enhances efficiency

- Windows 10 compatibility enables highest performance and safe operation with state-of-the art software

- Comprehensive alignment functions

- Simplified operation for inexperienced users

|